Description

The Peak Gas Generation’s i-Flow nitrogen generator is amongst the best in its class of pressure swing adsorption (PSA) based nitrogen gas generator systems. Harnessing the latest air separation technologies, i-Flow delivers high quality, industrial grade nitrogen gas, at flow rates & purities that can meet the demands of any industry. Regardless of your application, an i-Flow PSA nitrogen generator provides an energy efficient, low cost alternative to bulk nitrogen supply methods.

- Control the cost of nitrogen gas supplies

- Improve productivity & reduce downtime

- Drive operational efficiencies

- Meet sustainability targets

i-Flow 6000 Series Nitrogen Generator: Product Description

i-Flow is a modular & scalable PSA nitrogen generator system that delivers a consistent, convenient & reliable nitrogen supply for numerous manufacturing and processing industries. With i-Flow you don’t need to buy nitrogen gas anymore, you can make it yourself on-site & on demand.

Some typical industry applications:

- Fire prevention

- Gas flushing & modified atmosphere packaging

- Nitrogen blanketing, inerting & purging

- Laser cutting

- Pressure transfer

- Sparging or stripping

Adaptable, innovative & reliable engineering

Peak has over two decades of experience manufacturing gas generation solutions and is one of the industry’s leading global nitrogen generator manufacturers. Designed & assembled in our UK based ISO 9001 facility, the i-Flow nitrogen gas generator has been built with reliability, robustness & economy in mind.

It is an energy efficient & highly diverse nitrogen generator system, that has been engineered specifically to be adaptive, as well as flexible to varying facility demands.

A single i-Flow nitrogen gas generator system can produce:

- Over 4000 litres per minute (240+ Nm3/hr)

- Purities ranging from 95-99.9995% (ultra-high purity nitrogen).

Regardless of whether your application needs food grade nitrogen gas or other varying purity grades, i-Flow can be configured to meet your specific requirements. Additionally, each generator is built with easy features/options for low cost retrospective expansion, with the addition of CMS columns or nitrogen generator unit modules, should you require to upscale production to meet future growth.

Our expert consultants design the complete nitrogen solution around your needs. With a range of options available, including the ability to fully integrate into facility monitoring & managements systems, your nitrogen gas generator system can be as advanced or simplistic as you want. Most importantly, we will ensure it always meets the full, seasonal & varying demands of your production facility.

Furthermore, you can have complete confidence in your Peak nitrogen generation system, which comes backed by a global aftercare service called [PEAK Protected], that is truly unique in our industry and is ultimately, what sets us apart from other nitrogen generator manufacturers.

Advantages over bulk nitrogen supply

With a Peak Industrial nitrogen generator, you can effectively eliminate:

- Rising prices to the cost of nitrogen gas supply

- Rental charges for nitrogen cylinder, dewars or micro-bulk tanks

- Cost of nitrogen cylinder or tank delivery & supply trucking

- Environmental & Hazmat surcharges

- Health & Safety risks over pressurized gas or liquid storage

Ultimately, a Peak nitrogen generation system offers your company the opportunity to eliminate the need to buy nitrogen gas in to maintain production and replaces this with a robust, sustainable & on-site nitrogen solution, that is not only cost effective, but far more dependable too.

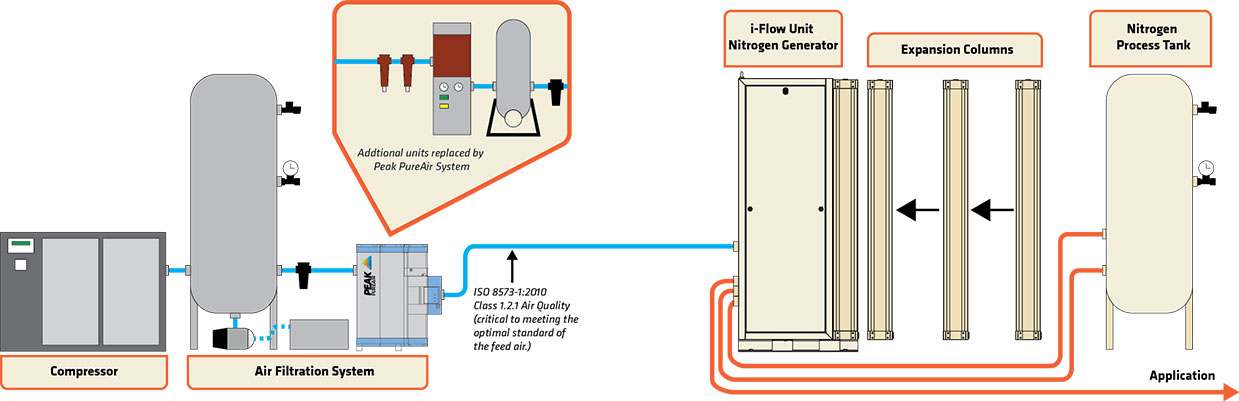

Typical Gas Generation System Installation

Whether you need food grade nitrogen gas or a nitrogen generator for laser cutting, every Peak Gas Generation nitrogen generation system we create is custom designed to meet your specific industry & unique nitrogen application requirements. Below is a typical illustration of what a complete Peak Gas Generation nitrogen generator system consists of, from end to end.