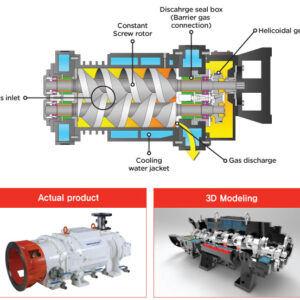

Description

Features and Benefits

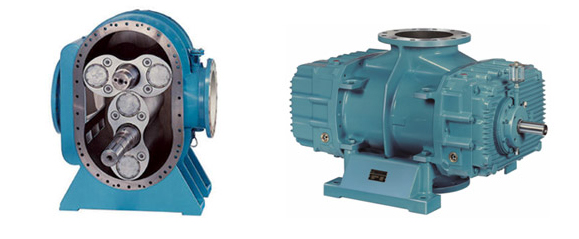

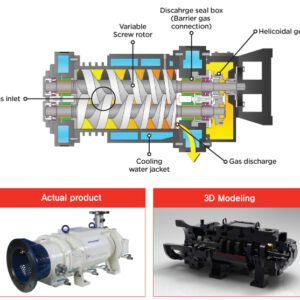

Superior mechanical durability due to the non-contact operation between the screw and cylinder inside the pump

02.Operational stability

Excellent operational stability and durability due to low-noise and low-vibration operation by precision machining and balancing

03.Various corrosion resistant coating

Various corrosion resistant coating

04.Excellent discharge capacity

Excellent continuous discharge capacity and continuous operational performance even in harsh process environment

05.A variety of optional features

Possible to apply flushing, purging and control system options according to the process characteristics

06.Echo friendly & economical operation

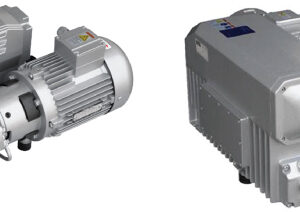

- Economical and eco-friendly dry operation without using water and oil

- Superior efficiency compared to a vacuum pump single model (degree of vacuum and capacity in relation to power)

07.Flange-type motor with IEC standards

Accurate and easy to assemble due to application of flange-type motor with IEC standards, and noise reduction realized through the optimal alignment assembly by machining tolerances

08.Easy maintenance

Easy maintenance and cost savings due to simple structures by optimal design

Technical Data

| Tape of construction | Theor.intake volume folw Sth in case of peration with 50Hz/60Hz | Max.admissi-differen-tral pressure in case of motor riting | oil Filling quantities for | Motor rating at 50Hz/60Hz | Motor size | Speeds at 50Hz/60Hz | System voltages at | |||

|---|---|---|---|---|---|---|---|---|---|---|

| GMa/b | GLa/b | 50Hz | 60Hz | |||||||

| [㎥/h] | [mbar] | [litre] | [litre] | [kW] | [1/min] | [v] | [v] | |||

| Gma/GLa | 10.0HV | 180/220 | 130 | 0.9 | 0.7 | 0.75/0.85 | 80 | 3000/3600 | 230/400 | 440-480 |

| Gma/GLa | 10.1HV | 250/300 | 140 | 0.9 | 0.7 | 1.1/1.32 | 80 | 3000/3600 | 230/400 | 440-480 |

| Gma/GLa | 10.2HV | 365/450 | 130 | 0.9 | 0.7 | 1.5/1.8 | 90s | 3000/3600 | 230/400 | 440-480 |

| Gma/GLa | 11.3HV | 500/600 | 140 | 1.1 | 0.8 | 2.2/2.6 | 90L | 3000/3600 | 230/400 | 440-480 |

| Gma/GLa | 11.4HV | 750/900 | 130 | 1.1 | 0.8 | 3/3.6 | 100L | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 12.5HV | 1000/1200 | 130 | 1.5 | 1.1 | 4/4.8 | 100L | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 12.6HV | 1430/1700 | 130 | 1.5 | 1.1 | 5.5/6.3 | 112L | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 16.f7 HV | 2000/2400 | 110 | 2.5 | 2.1 | 7.5/8.8 | 132S | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 13.8 HV | 2900/3450 | 100 | 2.5 | 2.1 | 11/12.5 | 160M | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 14.9 HV | 3900/4700 | 80 | 7 | 3.5 | 11/12.5 | 160M | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 15.10 HV | 5600/6700 | 80 | 12 | 5.4 | 15/17 | 160M | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 15.11 HV | 7500/9000 | 80 | 12 | 5.4 | 18.5/21.0 | 160L | 3000/3600 | 400/690 | 440-480 |

| Gma/GLa | 16.f13 HV | 8150/9800 | 75 | 11 | 7.6 | 18.5/21.0 | 180M | 1500/1800 | 400/690 | 440-480 |

| Gma/GLa | 16.13 HV | 9750/11700 | 75 | 11 | 7.6 | 22/25 | 180L | 1500/1800 | 400/690 | 440-480 |

| Gma/GLa | 17.15 HV | 16000/18825 | 60 | 18.5 | — | 30/36 | 200L | 1500/1800* | 400/690 | 440-480 |

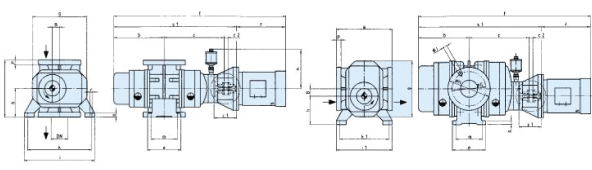

General Drawing