Techcon offers the optimal solution for the installation of air compressor systems. Because if the system is not properly installed, it will lead to many problems:

- Machine operation is not stable

- Energy loss

- Pressure loss

- Machine room temperature rises, causing machine failure

- Poor quality of compressed air due to generation of water and oil.

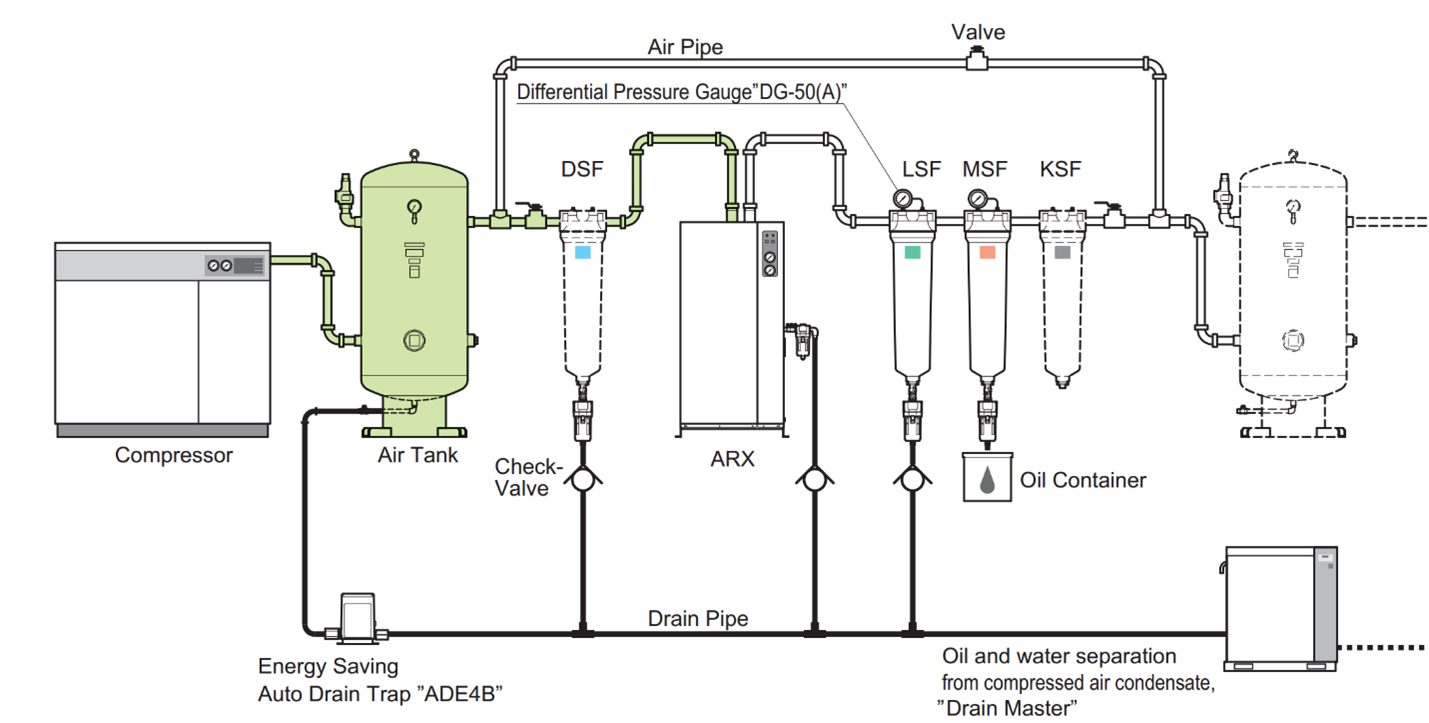

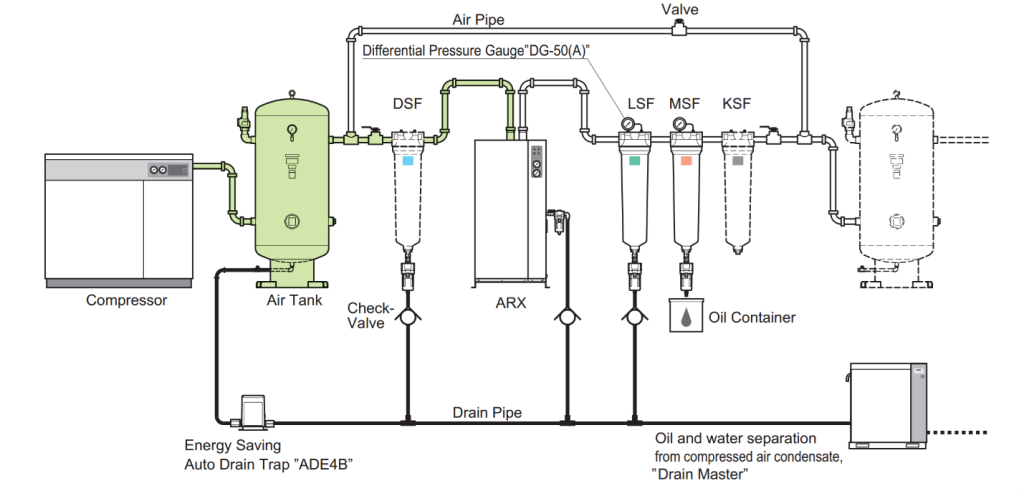

Select the order of installation of equipment in the air compressor system:

The equipment is arranged in order to suit the function and condition of the air compressor room:

The position of the filter on the pipeline depends on the type as well as the recommendations of the manufacturers. The water filter is placed in front of the air dryer, the other filters are usually placed after the air dryer

Location of accumulator: The accumulator can be placed before or after the air dryer, depending on the condition of the machine room. Each position has different advantages and disadvantages:

- Partial separation of water from the compressed air: The tank in front of the dryer is more optimal.

- Pressure stabilization for the air compressor: The tank in front of the dryer is more optimal

- Does not radiate heat into the room: The bottle placed behind the dryer is more optimal

- No water taking up the volume of the tank: The tank is placed behind the dryer for better results

- Pressure stabilization for the factory: The tank placed behind the dryer is more optimal

- Do not cause local overload for the dryer: The tank placed behind the dryer is more optimal

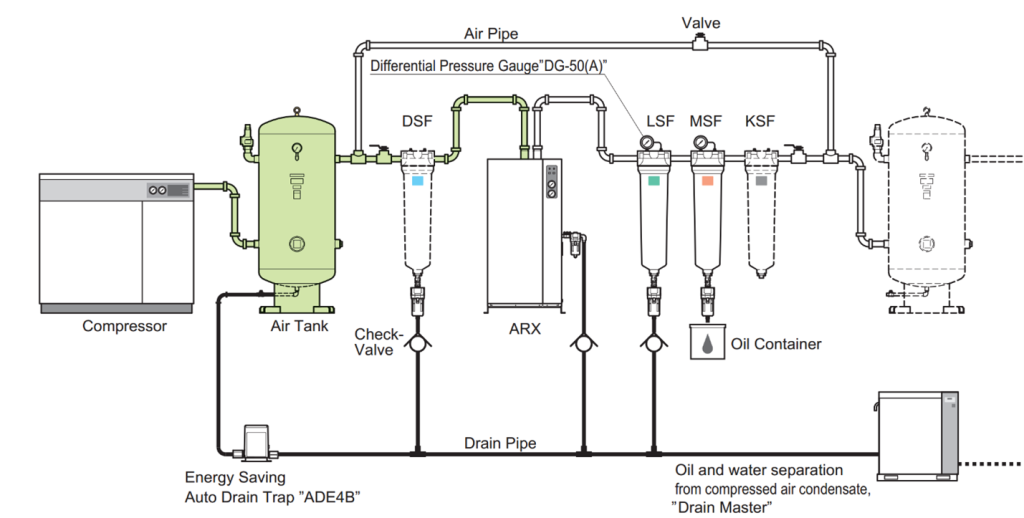

Installation of compressed air piping system:

The pipeline plays the role of conducting compressed air from the air compressor system to the air use area. The correct installation is extremely important because it not only affects the quality of compressed air, but also affects the air pressure as well as the stability of use:

- Choose the right pipe size according to the load air flow

- Choose the type of pipeline to minimize change of direction, in order to reduce the loss of gas pressure

- Choose the right pipeline diagram so that the pressure is most stable (A loop is the most optimal)

- Choose the right type of pipe branching to avoid water stagnation and damage to equipment

- Choose the type of pipe installation depending on the size and scale of the pipe (welded, threaded, flanged, etc.)

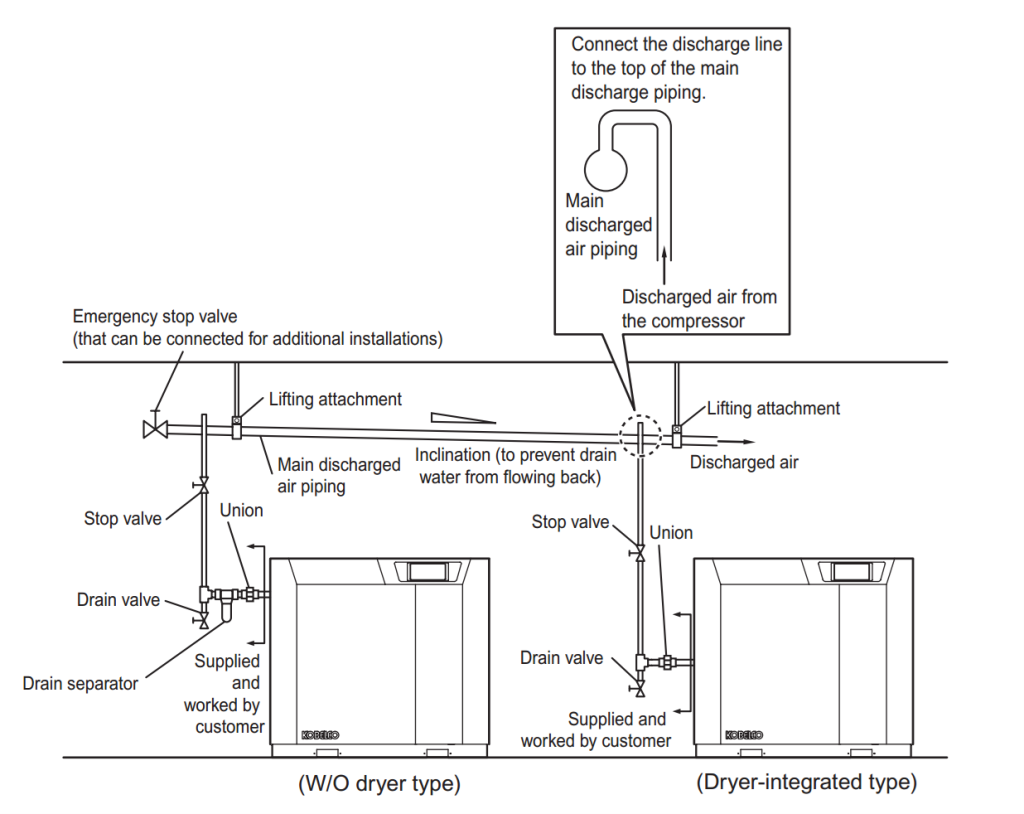

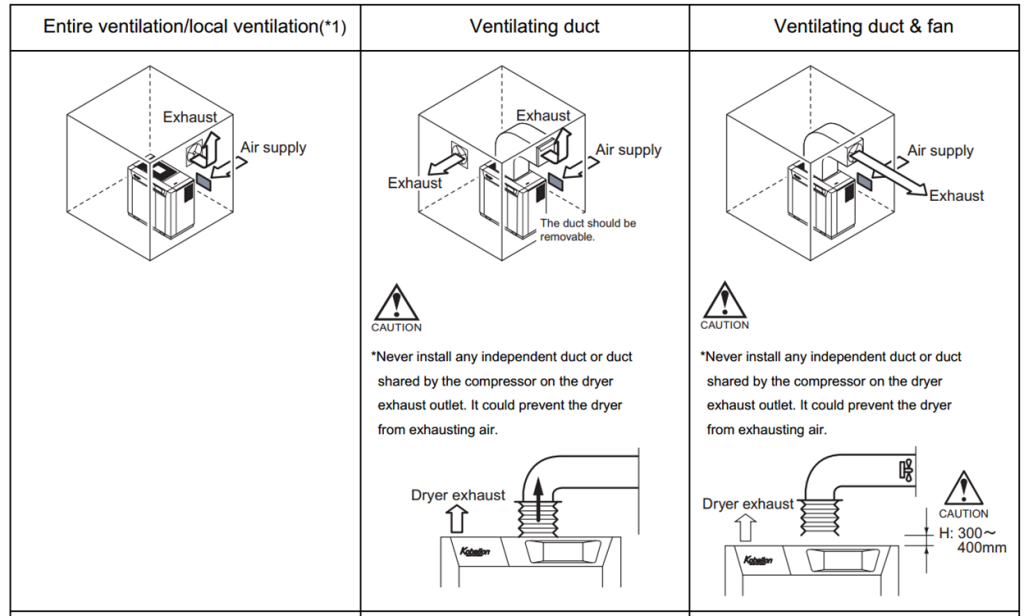

Install hot air outlet duct

An air compressor is a device that generates a lot of heat. Therefore, this hot air needs to be discharged from the room to avoid thermal resonance and cause machine failure.

- Heat emitted from the air compressor/air dryer cooling rig needs to be led out through the duct system (Exhaust Ventilation Duct). The design of the air duct depends on the machine capacity, equipment layout as well as the type of air compressor.

- Heat released into the room needs to be discharged through the room exhaust fan. This fan both helps to remove excess heat and acts as an exhaust fan to draw fresh air into the room

- Fresh air intake should be arranged convection with hot air exhaust to avoid heat accumulation. This door needs to arrange a dust filter and shutters to both increase the intake air area and remove coarse dust and insects

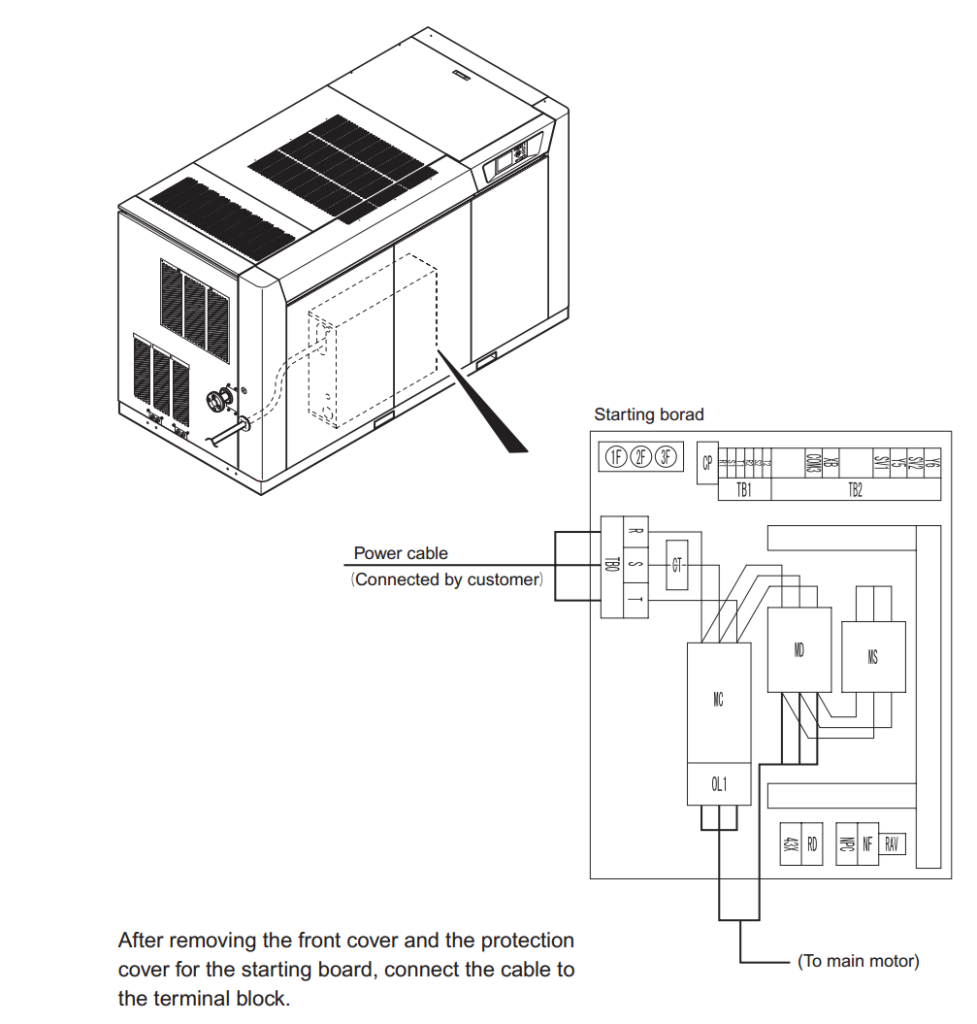

Installation of electrical systems:

The electrical system includes: Electrical cabinets (including breakers), electric cables, cable tray ladders. The selection of these devices should be in accordance with the standards, to avoid being too small (dangerous, disconnecting) or too large (causing waste, not promoting the protection function).

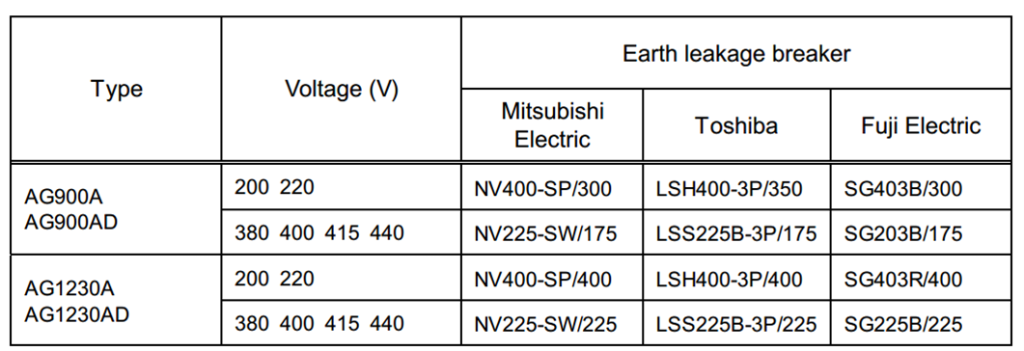

- Breakers need to choose the right capacity, the right type according to the manufacturer’s recommendations

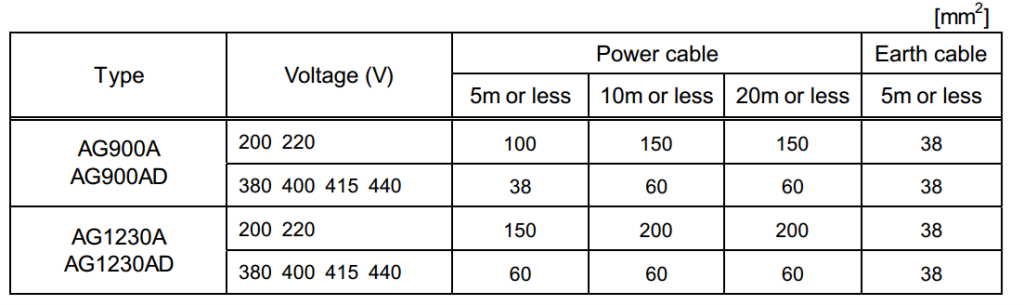

- The power cable needs to be selected to match the machine’s capacity and the distance from the machine to the electrical cabinet. The selection is according to the manufacturer’s recommendations

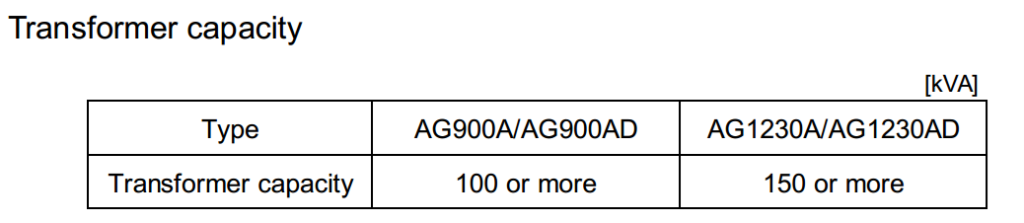

- Substation: The air compressor consumes a lot of power, so it is necessary to calculate the substation enough to not affect the total capacity of the station. The choice of station capacity depends on the machine capacity as well as the manufacturer’s recommendations:

Installation of sewer line

Air compressors, air dryers, accumulators and air purifiers all release large amounts of water. Most of this water is mixed with oil, so it is necessary to install a pipeline to bring wastewater out of the engine room to the treatment area to separate the oil from the water.

Techcon will advise on overall installation solutions as well as professional construction of the entire system. Contact us for the best service!.