Air compressors are equipment that operate under heavy loads, generate heat continuously, and play an important role in the plant. Therefore, the machine needs to be maintained and maintained on a regular basis, professionally to avoid potential problems.

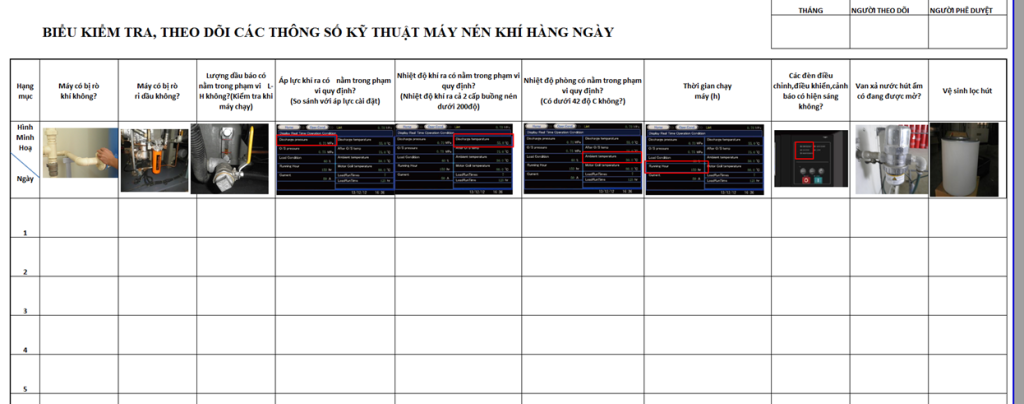

Daily maintenance

This is an extremely important job, it not only helps the machine operate safely, but also significantly reduces power consumption as well as timely adjusts machine parameters! Commonly performed tasks:

- Check the overall operating parameters of the machine

- Cleaning basic items (dust filter, air filter …)

- Timely detection of unusual problems to immediately contact the supplier in case of need

Techcon will provide a daily test form as well as detailed step-by-step instructions. In addition, Techcon is also available 24/7 for all communications, needing help from customers to help the system operate safely and efficiently!

Regular maintenance:

Consumables and components need to be replaced periodically, which not only helps the machine avoid potential problems, but also greatly improves the machine’s operating efficiency. Usually there are levels:

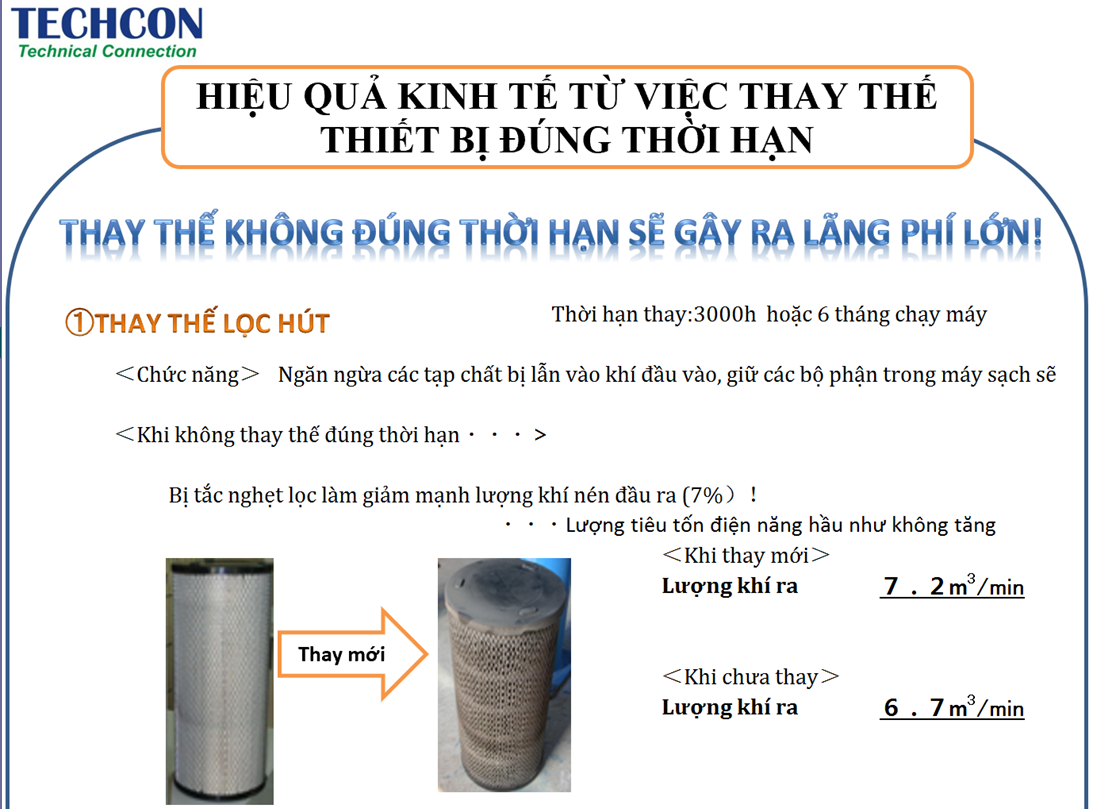

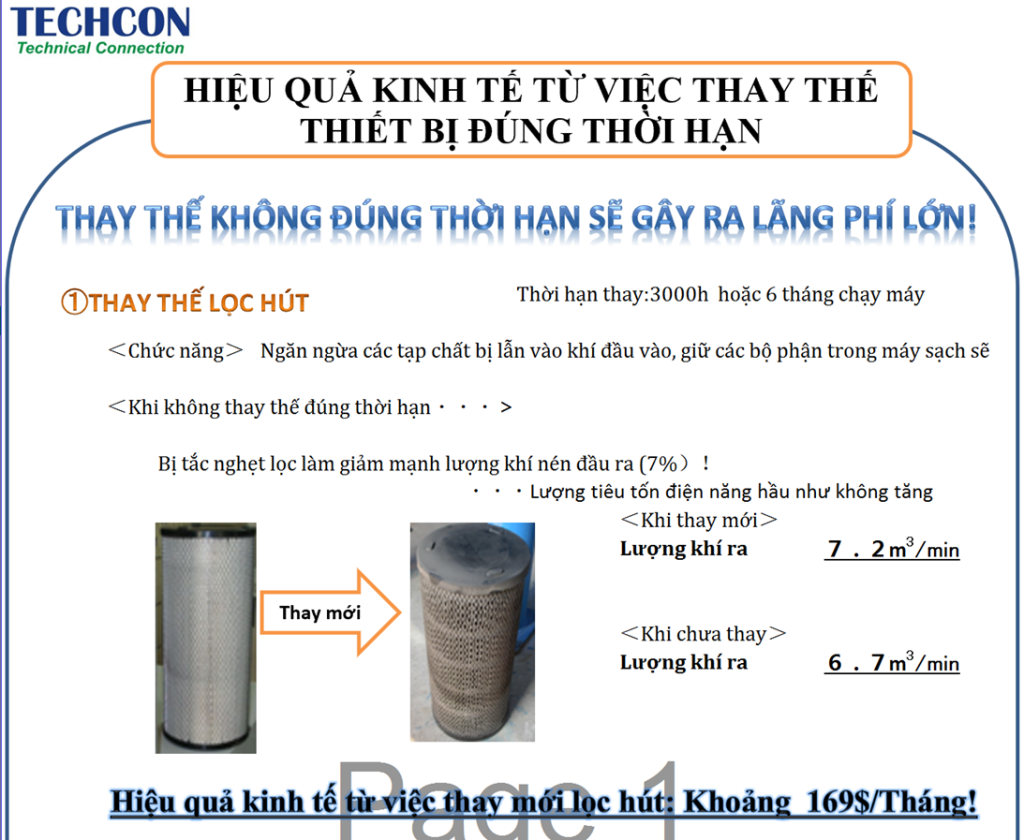

- Level Five Maintenance: Replace simple supplies such as: Air filter, oil filter, oil separator filter (With oil-based compressors), exhaust filter (With oil-free air compressors) and engine oil

- Medium Maintenance: This is the level that concerns the engine as well as some air valves. This level greatly improves the performance and safety of the machine

- Overhaul maintenance: This is a major level of maintenance, replacing most of the important components, including the bearings of the compression chamber (with oiled machines) even replacing the compressor chamber (with oil free machines). This level makes the machine almost completely refreshed and the performance is close to the new machine

Techcon provides genuine supplies as well as performs professional maintenance for all levels of maintenance. In addition, we also provide free inspection service for customers once every 3 months during the life of the machine. This helps the machine to be monitored and detect potential problems in time, reducing the risk of serious failures!!