Description

FIRE PREVENTION FUME COLLECTOR (Countermeasures against fire)

- Have a function to prevent the sparks-sputter from going into the filter box.

- Have functions to absorb heat to sparks and to prevent ignition.

- Sparks and smoke sensor auto shutdown system.

- With a circle flow separator and heat absorber roller.

Molded cartridge filter

Material: Polyester

Surface treatment: –

Corresponding models: PiE, FCN, Mi and PiH

Application: General dried particles (particle diameter about 10μm)

Features

- For dust having a particle diameter of about 10μm.

- Collecting efficiency: Good, Particle diameter about 10μm

- Heat resistant temperature (F): Normal temperature 40˚C (104˚)

- Dust removal: Pulse jet

Various types of filters are available

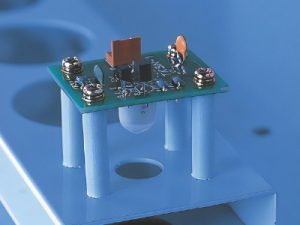

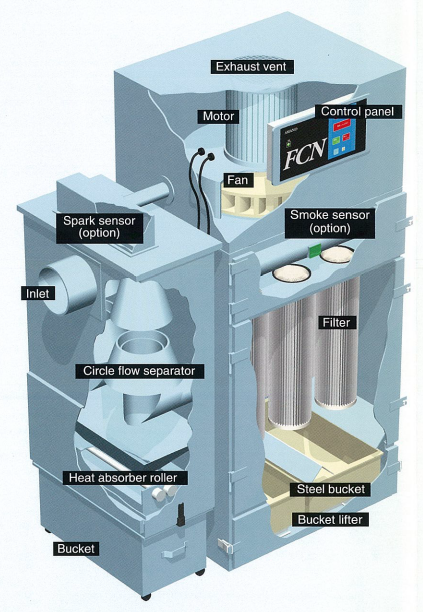

Spark & Smoke Sensor

Sparks sucked into the dust collector are detected by an infrared sensor. Fire breaks out inside the dust collector is detected by a smoke sensor. If a spark enters or a fire inside the dust collector is detected, the dust collector will automatically stop. The safe design protects your facility from fire.

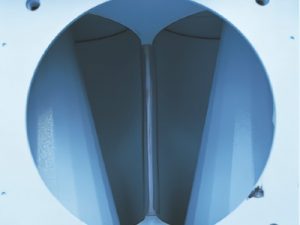

Circle Flow Separator

Primary separation and heat absorption of dust suctioned into the circle flow separator prevents fires from ignition.

This process separates out more than 70 percent of dust. Lightening the load on the filter in this way gives the filters a longer service life.

Heat Absorber Roller

Sparks and inflammable dust separated by the circle flow separator are prevented from combusting by the energy absorption and the effect of the heat absorber roller, and inflammable dust is prevented entering the bucket. The energy absorption and dispersion effect of the metal roller work in preventing fires.

Bucket

Dust separated out by the circle flow separator collects in the bottom bucket, and dust after filtering collects in the bottom bucket of the dust collector. Dust can be removed just by releasing the locking clip and taking out the bucket.

Fire extinguisher port

In case of a fire inside the dust collector, you can extinguish the fire from the fire extinguisher port.

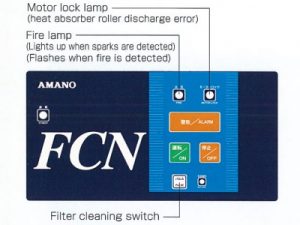

Control Panel

The panel is designed for good visibility. Warning lamp lights up when sparks or high-temperature dust enter the system. Warning lamp flashes to report that smoke (fire) occurred. Dust collector automatically comes to a stop when a problem occurs.

Filter Cleaning

The pulse jet method cleans the filter by instantly releasing the compressed air and plunging it into the filter. It operates automatically, so there is no need to bother the operator.

INTERNAL DESIGN

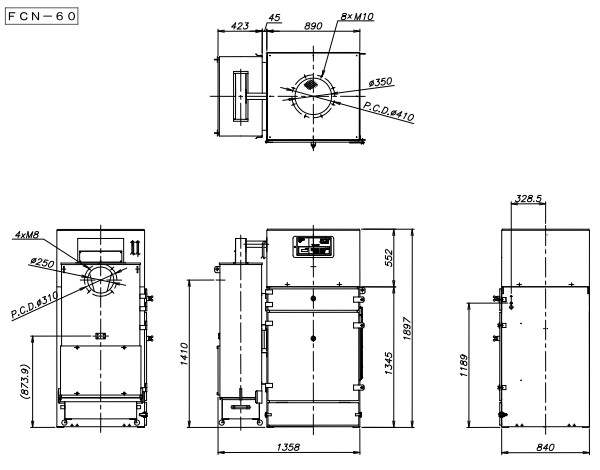

EXTERNAL VIEW

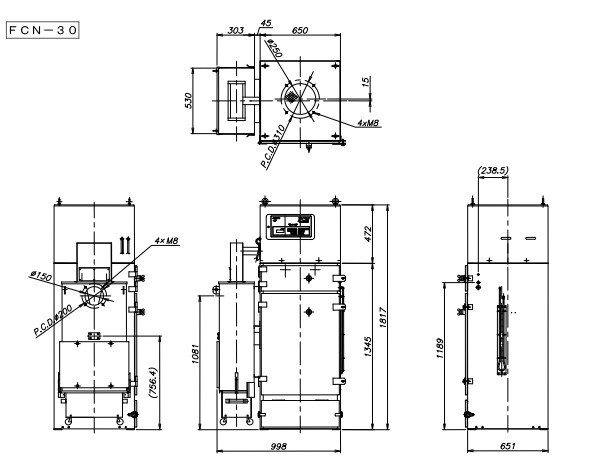

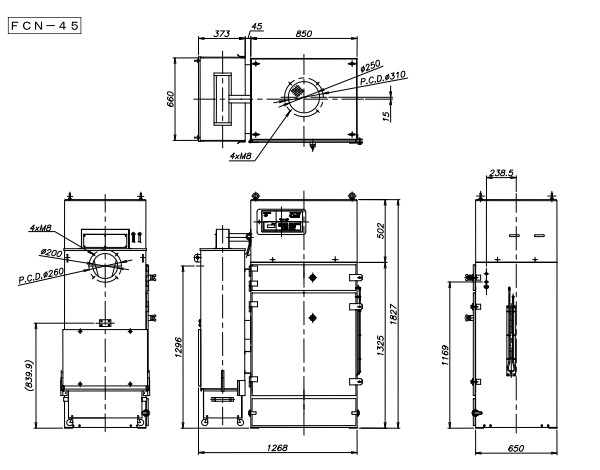

Unit(mm)

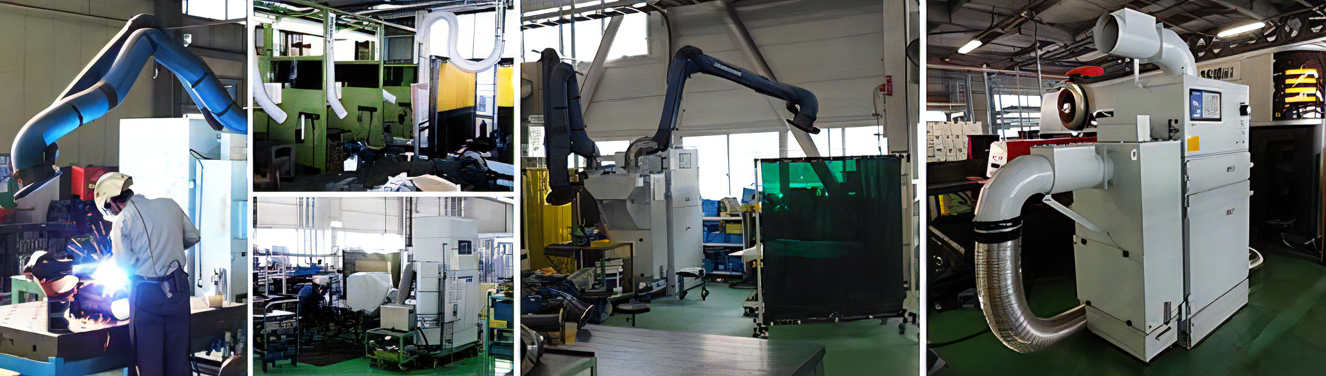

APPLICATION

- Plants running 24 hours a day and automated factories.

- Requiring a high degree of safety.

- Workplaces with fumes from laser machining.

- Workplaces with fumes from plasma machining.

- Workplaces with fumes and sparks in the air from welding and cutting metal.

SPECIFICATION

| Particular | Unit | FCN-30 | FCN-45 | FCN-60 | |

|---|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | 220 | |

| Frequency | Hz | 60 | 60 | 60 | |

| Phase | 3P | 3P | 3P | ||

| Output | kw/hp | 1.5/2.0 | 2.2/3.0 | 3.7/5.0 | |

| Max Airflow | m³/min | 18 | 30 | 45 | |

| Max. Static Pressure | kPa | 2.55 | 2.55 | 2.84 | |

| Filter Area | m² | 27.0 | 40.5 | 60.8 | |

| Suction Port Ø | mm | 150 | 200 | 250 | |

| Dimension (WxDxH) | mm | 998x651x1817 | 1268x660x1827 | 1358x840x1897 | |

| Weight | kg | 245 | 305 | 430 |