Description

Features:

Fine powder recovery machine from general powder to toner

- Handles ranging from common powder to toner.

- Layout-free model has a separate filter and blower unit.

- Prevention of contamination of powder collection

- Since the filter unit and blower unit are separated, the installation layout is flexible

- No leakage of collected powder

- Equipped with a shatterproof mechanism when discharging powder

- Can be operated continuously for 24 hours

A pulse jet method using compressed air is used to remove the powder adhering to the filter surface. It allows the recovery machine to operate continuously.

Long-lasting filter due to the built-in swirl flow type separator

The sucked air swirls along the inner surface of the cylindrical body, and only the air with a low powder concentration inside passes through the filter. The powder on the outside where the powder concentration is high goes directly into the bucket. It also significantly reduces filter wear.

The filter replacement work can be easily done by simply opening the upper part of the main body. The new resin filter used in the IX series has a lifespan of 3 to 5 times (compared to our company) compared to conventional filter media, which greatly reduces maintenance man-hours.

“Anti-Explosion Dust Collector Type” for recovering powders that have a high risk of explosion

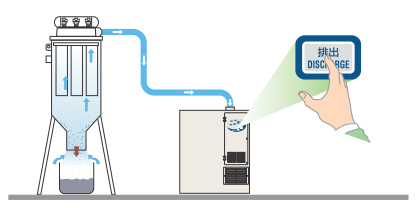

Equipped with a new recovery powder scattering prevention mechanism

We consider the health of workers and the hygiene of the working environment to be very important. When the recovered powder is discharged, the blower is operated at an ultra-low speed by inverter control to prevent the powder from scattering to the surroundings.

We consider the health of workers and the hygiene of the working environment to be very important. When the recovered powder is discharged, the blower is operated at an ultra-low speed by inverter control to prevent the powder from scattering to the surroundings.

* This mechanism is not built with IB-D series.

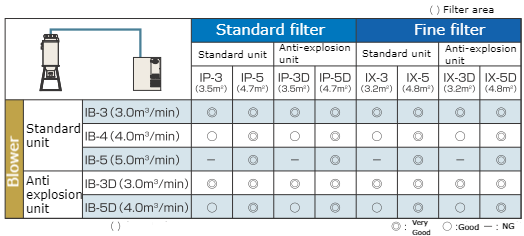

Filter Units

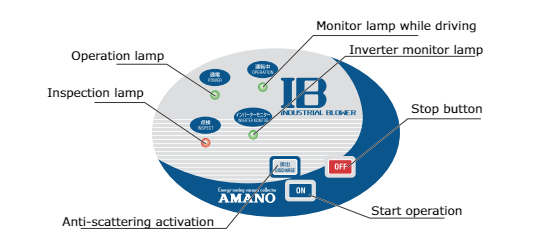

Blower Units

SPECIFICATION

| Particular | Unit | IP-3 | IP-3D | IX-3 | |

|---|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | 220 | |

| Frequency | Hz | 60 | 60 | 60 | |

| Max. Static Pressure | kPa | 5.39 | 6.08 | 6.37 | |

| Filter Material | POLYESTER | POLYESTER | POLYETHYLENE | ||

| Filter Area | m² | 3.5 | 3.5 | 3.2 | |

| Suction Port Ø | mm | 50.8 | 50.8 | 50.8 | |

| Dimension (WxDxH) | mm | 653x658x1409 | 881x658x1537 | 651x654x1568 | |

| Weight | kg | 65 | 83 | 65 |

| Particular | Unit | IX-3D | IP-5 | IP-5D | |

|---|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | 220 | |

| Frequency | Hz | 60 | 60 | 60 | |

| Max. Static Pressure | kPa | 5.88 | 5.88 | 5.88 | |

| Filter Material | POLYETHYLENE | POLYESTER | POLYESTER | ||

| Filter Area | m² | 3.2 | 4.7 | 4.7 | |

| Suction Port Ø | mm | 50.8 | 63.5 | 63.5 | |

| Dimension (WxDxH) | mm | 879x654x1696 | 653x658x1609 | 881x658x1737 | |

| Weight | kg | 83 | 70 | 88 |

| Particular | Unit | IB-3 | IB-4 | IB-5 | |

|---|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | 220 | |

| Frequency | Hz | 60 | 60 | 60 | |

| Phase | 3P | 3P | 3P | ||

| Output | kw/hp | 1.5/2 | 3.7/4 | 5.5/7.3 | |

| Max Airflow | m³/min | 3 | 5 | 6 | |

| Max. Static Pressure | kPa | 13 | 23.5 | 27 | |

| Motor Type | STANDARD | STANDARD | STANDARD | ||

| WITH INVERTER | YES | YES | YES | ||

| Suction Port Ø | mm | 76.3 | 76.3 | 76.3 | |

| Dimension (WxDxH) | mm | 700x500x608 | 700x500x850 | 700x500x850 | |

| Weight | kg | 90 | 130 | 155 |

| Particular | Unit | IB-3D | IB-5D | |

|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | |

| Frequency | Hz | 60 | 60 | |

| Phase | 3P | 3P | ||

| Output | kw/hp | 2.2/3 | 5.5/7.3 | |

| Max Airflow | m³/min | 5 | 5 | |

| Max. Static Pressure | kPa | 12 | 22 | |

| Motor Type | EXPLOSION PROOF | EXPLOSION PROOF | ||

| WITH INVERTER | NO | NO | ||

| Suction Port Ø | mm | 76.3 | 76.3 | |

| Dimension (WxDxH) | mm | 600x430x776 | 750x520x866 | |

| Weight | kg | 105 | 187 |