Description

Features

- Intelligent Dust Collector with Auto Pulse Jet Type

- Middle Air Volume from 60 to 180㎥/min

- 5.5kW/7.5kW/11.0kW Package type dust collector

- Differential pressure sensor

- User-friendly message

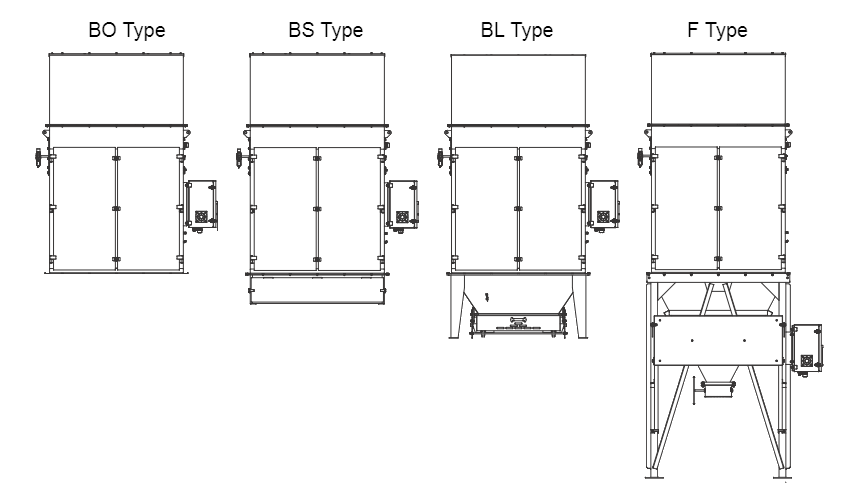

- Various combinations of dust discharge

Molded cartridge filter

Features:

Material: Polyester

Surface treatment: –

Corresponding models: PiF

Application: General dried particles

- Collecting efficiency: Good, For dust having a particle diameter of about 10μm.

- Heat resistant temperature (F): Normal temperature 40˚C (104˚)

- Dust removal: Pulse jet

7 types of filters are available

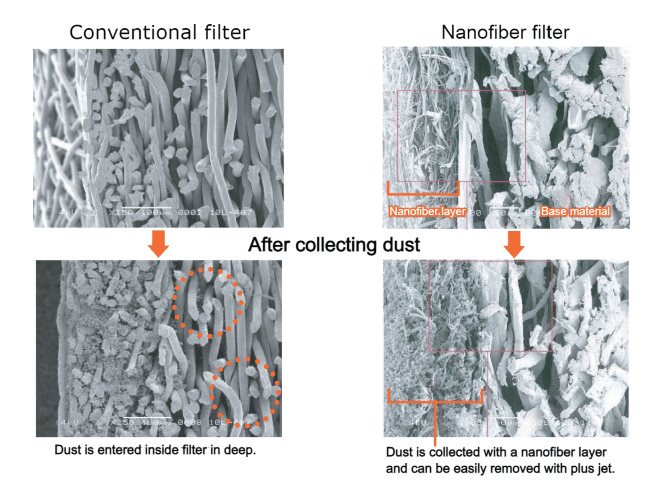

Nanofiber filter option without extra cost

- The nanofiber filter area is about 2.5 times larger than the standard filter.

- Dust is collected with a nanofiber layer and easily removed with a plus jet.

- By large filter area and a reduction in the filter filtration speed, make life of the filter larger than ever.

- Nanofiber has a self-extinguishing function, it prevents fire from the dust collectors.

Automatically controls the fan speed

The built-in inverter automatically operates with the set value of air volume. (Fixed motor rotation speed is also possible)

Automatic pulse jet

Automatically start the pulse jet for filter cleaning

Automatic data logging

QR code will be displayed and get error and operation history. It can be retrieved as CSV data.

Automatically notify the status of the filter condition

The condition (differential pressure) of the filter is displayed on the LCD as an icon.

Remote control

It can be operated in conjunction with a production machine.

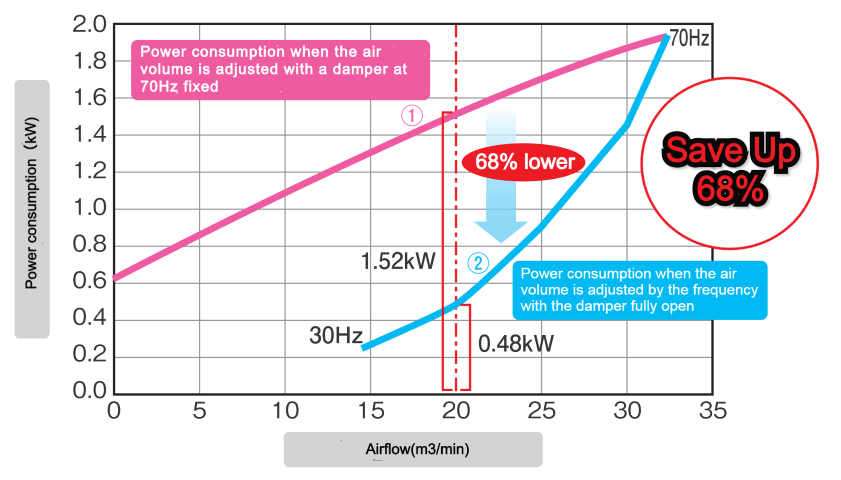

Inverter control

– Air volume control by an inverter is superior in energy saving effect to volume control by a damper.

– By automatically operating with the air volume set by the inverter, it is possible to prevent excessive volume operation that causes clogging of the filter.

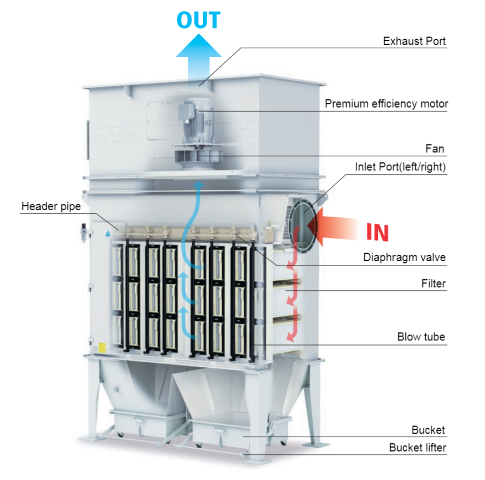

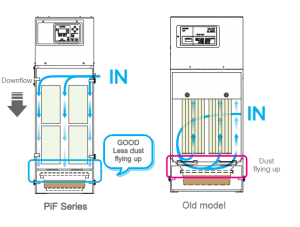

Downflow

The downflow reduces flying dust inside the dust collector and prevents dust reattachment. It suppresses the increase in filter pressure loss and improves the filter removal performance.

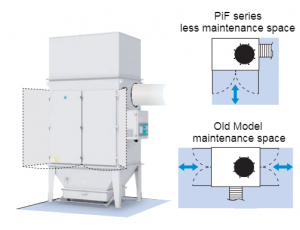

Reduce installation and maintenance space

There are no restrictions on the installation space. it is easy to install and easy to maintain.

Internal Structure

Various combination

Sample Installation

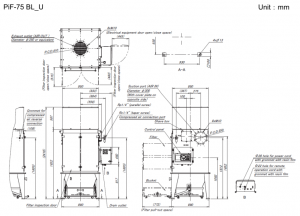

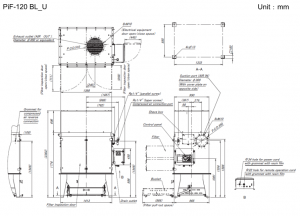

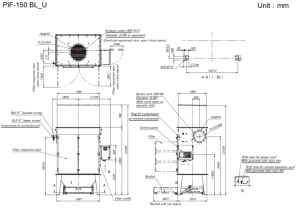

External View

PIF-75BL Type

PIF-75BL Type

PiF-120 BL Type

PiF-120 BL Type

PiF-150 BL Type

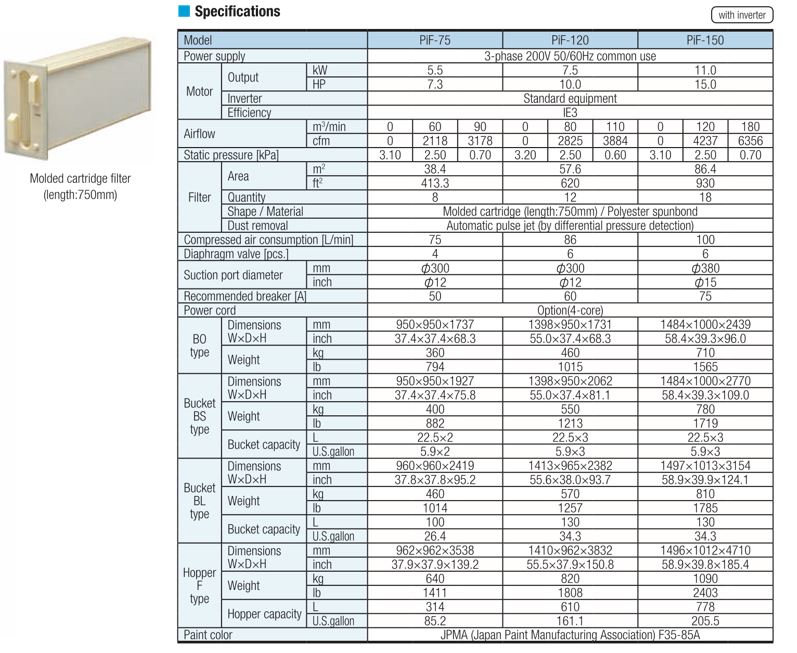

SPECIFICATION

| Particular | Unit | PiF-75 | PiF-120 | PiF-150 | |

|---|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | 220 | |

| Frequency | Hz | 60 | 60 | 60 | |

| Phase | 3P | 3P | 3P | ||

| Output | kw/hp | 5.5/7.3 | 7.5/10 | 11/15 | |

| Airflow | m³/min | 60 | 80 | 120 | |

| Static Pressure | kPa | 2.50 | 2.50 | 2.50 | |

| Suction Port Ø | mm | 300 | 300 | 380 | |

| Dimension BL Type (W x D x H) | mm | 950×950×2419 | 1398×950×2382 | 1484×1000×3154 | |

| Weight | kg | 450 | 570 | 800 |