Description

Features:

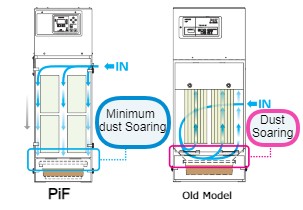

Amano’s medium-pressure pulse jet dust collector was designed with revolutionary concepts in particle collection.

- Sufficient suction is maintained even with narrow hoses

- An inverter allows for flexible operation.

- Situations where a long duct hose is used to collect dust

- The compact design requires a minimum amount of floor space.

- Continuous maintenance-free operation.

- Pulse-jet automatic filter cleaning operation.

Material: Polyester

Surface treatment: –

Corresponding models: PiF

Application: General dried particles

Features

- Collecting efficiency: Good, For dust having a particle diameter of about 10μm.

- Heat resistant temperature (F): Normal temperature 40˚C (104˚)

- Dust removal: Pulse jet

Various types of filters are available

Introducing AMANO’s Medium Pressure Dust and Chip collector units designed with revolutionary concepts in Dust and Chip extraction.

Unlike ordinary dust collectors, it can suck up airborne dust, high-speed flying dust, and cutting dust at the same time, and unlike vacuum cleaners, it can run continuously.

APPLICATION

SPECIFICATION

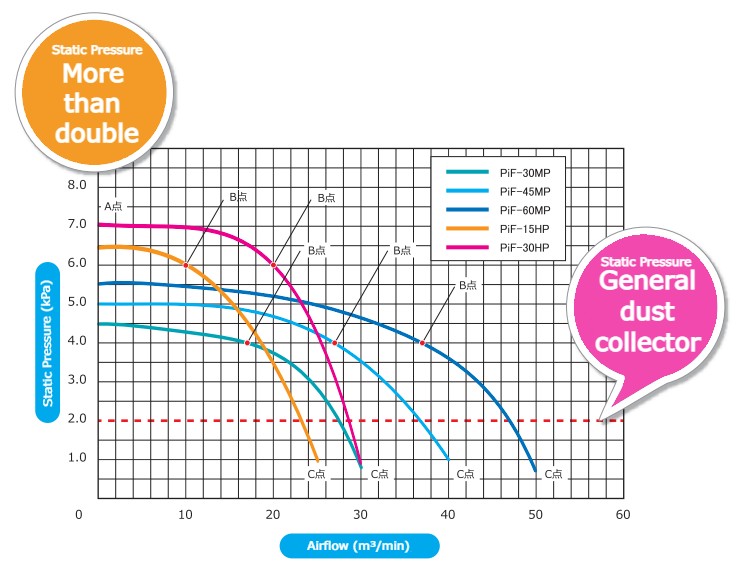

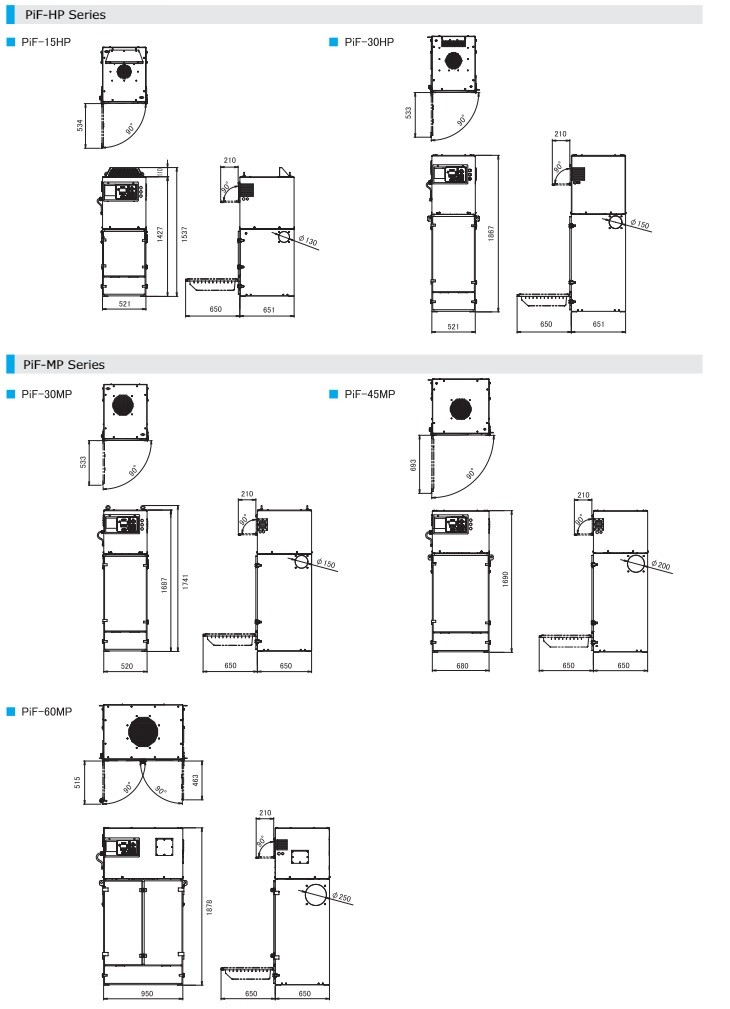

PiF-MP Series Maximum operating point static pressure 4kPa type

| Particular | Unit | PiF-30MP | PiF-45MP | PiF-60MP | |

|---|---|---|---|---|---|

| Power Supply | Volt/Phase/Hz | 220V/3P/60Hz | 220V/3P/60Hz | 220V/3P/60Hz | |

| Output | kw | 2 | 3.1 | 5.5 | |

| Max Airflow | m³/min | 30 | 40 | 50 | |

| Max Static Pressure | kPa | 4.5 | 5 | 5.5 | |

| Suction Port | Ø mm | Φ150 | Φ200 | Φ250 | |

| Dimension(W x D x H) | mm | 520×650×1687 | 680×650×1690 | 950×650×1878 | |

| Weight | kg | 189 | 246 | 350 |

PiF-HP Series Maximum operating point static pressure 6kPa type

| Particular | Unit | PiF-15HP | PiF-30HP | |

|---|---|---|---|---|

| Power Supply | Volt/Phase/Hz | 220V/3P/60Hz | 220V/3P/60Hz | |

| Output | kw | 3.1 | 5.5 | |

| Max Airflow | m³/min | 25 | 30 | |

| Max Static Pressure | kPa | 6.5 | 7 | |

| Suction Port | Ø mm | Φ127 | Φ150 | |

| Dimension (W x D x H) | mm | 521×651×1537 | 521×651×1867 | |

| Weight | kg | 196 | 267 |