Description

OVERVIEW

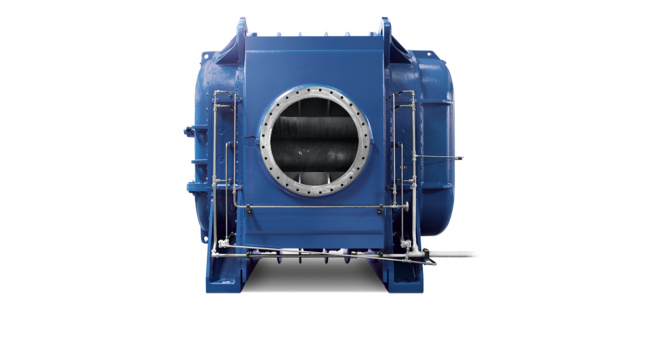

BLOWER POWER FOR SPECIAL APPLICATIONS

GQ process gas blowers are ideal for use in steel plants for the compression of process, cooling, and seal gas. These blowers are often used as 2-stage units and are up to the most extreme challenges.

FIELDS OF APPLICATION:

- Typically used in direct reduction plants for conveying of process and cooling gas. Operating pressure range up to max. pe=2.5 bar where the medium has the corresponding inlet pressure. The maximum pressure difference is 1100 mbar.

- Typically used in direct reduction plants for conveying of process- and cooling gas. Operating pressure range up to max. pe=6 bar where the medium has the corresponding inlet pressure. The maximum pressure difference is 1500 mbar.

DESIGN:

- Housing compression-proof for PN 2,5. Cylinder with noise reducing chamber on the discharge side, housing with connections for water injection – and water flushing, as well as for lubrication – and purge oil supply systems.

- Housing compression-proof for PN 6 (only GQ 20f20 and GQ 21.21). Cylinder with noise reducing chamber on the discharge side, housing with connections for water injection – and water flushing, as well as for lubrication – and purge oil supply systems.

SHAFT SEALINGS:

- Conveying chamber by single-acting oil-purged mechanical seals in combination with labyrinth seals.

- Drive shaft is sealed by 3 radial seal rings.

DIRECTION OF FLOW:

Horizontal, selective to the left or to the right

DRIVE:

Either via flexibly coupled spur gear or direct coupling with drive motor. Via flexibly coupled spur gear.

TEACHNICAL DATA

TYPE OF TECHNOLOGY

POSITIVE DISPLACEMENT BLOWERS

VOLUME FLOW

8,829 to 58,860 CFM

MEDIUM

PROCESS GASES , COOLING GASES

CONVEYING

OIL-FREE

NEGATIVE PRESSURE

-7.25 psi

POSITIVE PRESSURE

36.26 psi

APPLICATIONS

PROCESS GAS BLOWERS FROM AERZEN FUNCTION RELIABLY IN ALL INDUSTRIES, IN ALL MARKETS, AND IN ALL COUNTRIES ON EARTH.

AERZEN offers the process gas and coolant industries an incredibly broad spectrum of blower technologies – perhaps the broadest of any manufacturer. Machines that operate as stand-alones, in machine or container combinations, onshore and offshore. In every single key industrial application:

CHEMICAL AND PETROCHEMICAL INDUSTRIES

- Compression of H2 and CH mixtures

- Acetylene

- Ethylenes

- Lime kiln gas

- Rich gas

- Synthesis raw gas

- Butadiene

- Vinyl chloride

- Hydrogen sulphide

- Hydrogen

REFINERIES

- Hydrocracking

- Hydrosulphurisation

- Fractionating

- Reforming

- Catalytic cracking

- PSA

- Flare gas

- Compression of H2 and CH mixtures Energy production

- Gas turbine supply

- Steam

OIL & GAS CONVEYANCE AND STORAGE

- VOC recovery

- Natural gas compression

- Pipeline booster

- Underground gas storage

INDUSTRIAL GASES

- Hydrogen generation

- Air separation

- Argon

- Syngas Coolant industry

- Coolants (R1270, R290, etc.)

HELIUM REFRIGERATOR AND LIQUEFIER

- Helium

OFFSHORE

- Natural gas compression

BREWERIES

- Waste steam

Reviews

There are no reviews yet.