Description

Benefits of the R5 RA series

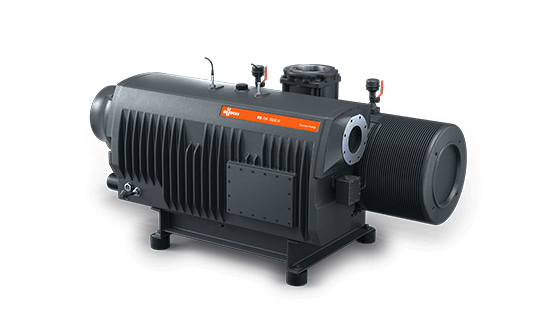

R5 RA oil-lubricated rotary vane vacuum pumps are real all-rounders. They have been designed for a wide range of industrial applications, for example, vacuum packaging, food processing, pneumatic conveying, plastics processing, and many more.

These vacuum pumps are characterized by high pumping speeds even in low-pressure ranges and therefore rapid evacuation times.

They feature highly durable high-performance vanes as standard, ensuring excellent performance and long service life.

R5 RA vacuum pumps are designed for continuous operation. An integrated float valve regulates the oil return depending on the oil level.

Vacuum pumps of the RA series are ultimate pressure-proofed. They can be operated continuously at ultimate pressure without overheating.

THE ALL-ROUNDER FOR COUNTLESS VACUUM APPLICATIONS

Reliable

Robust construction, highly resilient carbon fiber vanes, proven rotary vane technology, long service life

High performance

High pumping speed at low pressures, designed for continuous operation

Flexible

Various design options available, easy adaption to individual customer requirements and processes, level and temperature switch as standard

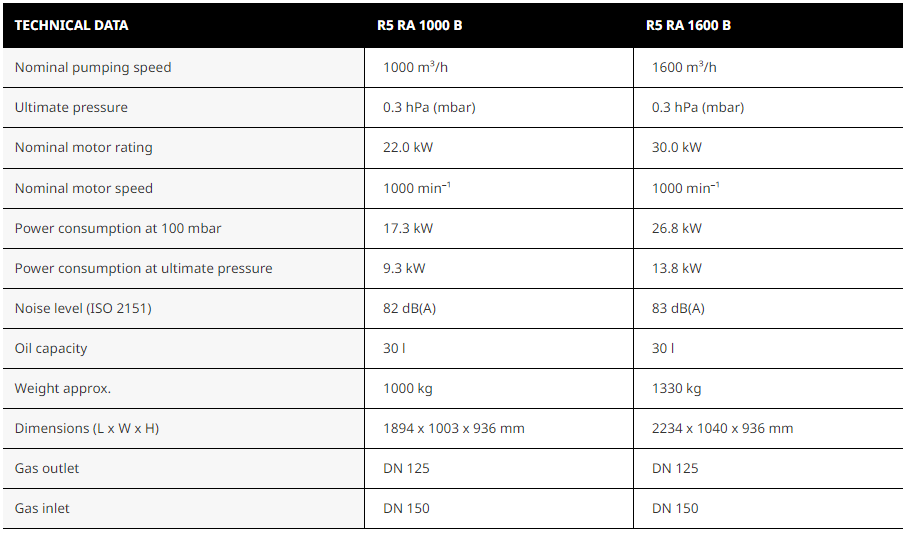

Technical Specifications

ISO 50Hz

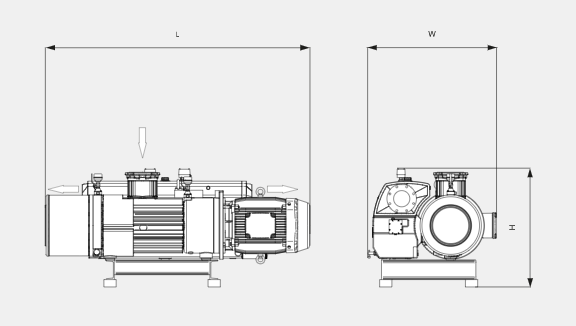

Dimensional drawing

R5 RA 1000/1600 B

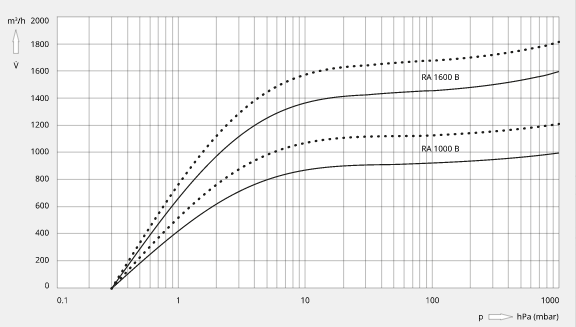

Pumping speed diagram

Air at 20 °C. Tolerance: ± 10%

Market & applications

Biogas handling

Electric power generation

Food processing

-

Pasteurizing

-

Sterilizing

-

Freeze drying

-

Powder processing

-

Vacuum cooling

-

Meat marinators

-

Meat tumblers

-

Meat cutters

-

Beverage filling

-

Pneumatic conveying of wet food waste

Hospitals and healthcare facilities

-

Vacuum-assisted closure (VAC)

-

Medical suction

-

Surgical vacuum draining

Oil and gas industry

-

Oil purification

-

Pipeline drying

-

Solvent extraction

Packaging

-

Round-table/Carousel packaging machines

-

Blister packaging

-

Tray sealers

-

Thermoforming packaging machines – Sealing/evacuation station

-

Chamber packaging machines large, industrial

Vapor recovery

-

Railcar and truck loading

-

Storage tank venting

-

Storage tank filling

-

Vapor balancing

-

Volatile organic compounds (VOC) recovery

-

Fueling

Accessories

- IEC (IE3) and NEMA motors

- Multi-voltage, multi-frequency motors (IE3)

- Optional variable speed drive

- Single or double gas-ballast valve, manual or solenoid operation

- Various inlet filters

- Inlet filter pressure gauge

- Various temperature and pressure gauges

- Starter units

- Oil mist separator

- Energy recuperation kit with heat exchanger

- Vacuum pump oils for all applications

Reviews

There are no reviews yet.