PROJECT INFORMATION

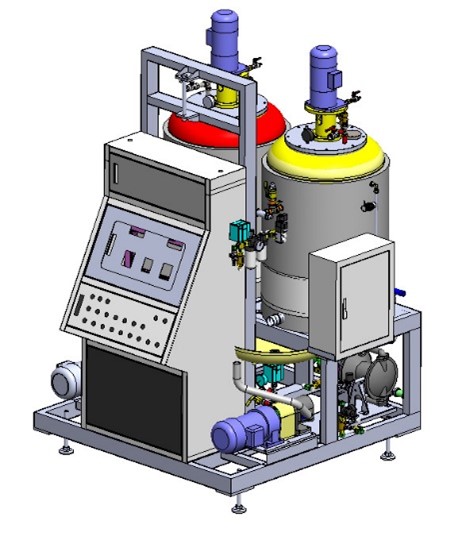

Project name: Low pressure polyurethane foam injection machine.

Project items: Design and construction and assembly of low pressure PU foam injection machine

Detailed introduction:

Polyurethane (PU) is a widely used material in industry, PU foam is used as an optimal solution to protect machinery and construction materials from environmental impacts, especially with Vietnam climate. With the high applicability of materials, Techcon provides customers with PU foam injection machines with high production efficiency, ensuring labor safety, products with good mechanical and chemical properties, and economical. raw materials and improve costs.

Working Principle:

In the unsprayed mode, 2 chemicals, Polyol and Isocyanate, are pumped and circulated from the tank to the mixing head and back to the tank. When the chemical passes through the heater, where the chemical will be cooled or heated depending on the climatic conditions and the temperature at which the chemical reacts best as advised by the chemical supplier. When spraying PU, the injector will open, chemicals enter the mixing chamber through the cake pump system and mix together there and then spray out. After spraying, the mixing head has an automatic washing mode (set to automatically wash) or washing by hand (press the button to wash). All parameters setting (chemical ratio, injection flow, chemical volume into the mold) are set very simply by pressing buttons on the control panel.

Technical improvements:

Using PLC and 3 inverters helps to optimize the function and automatically control the motors in the mixing process.