CUSTOMER INFORMATION

Customer name: Panasonic Vietnam Co., Ltd

Address: Thang Long Industrial Park, Lot J1 J2, Thang Long Bridge, Vong La, Dong Anh, Hanoi

PROJECT INFORMATION

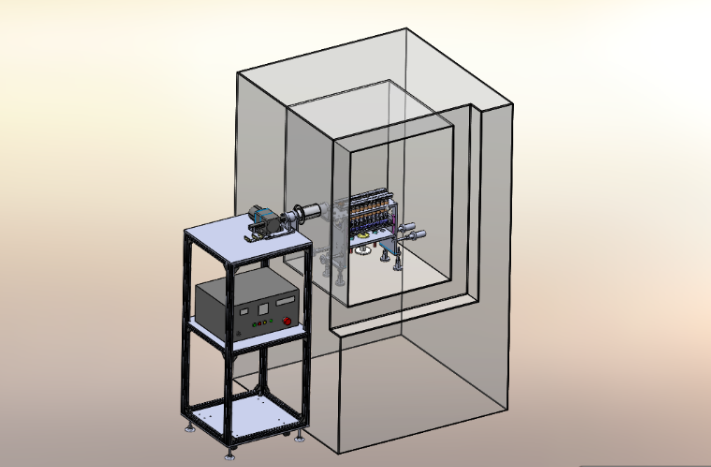

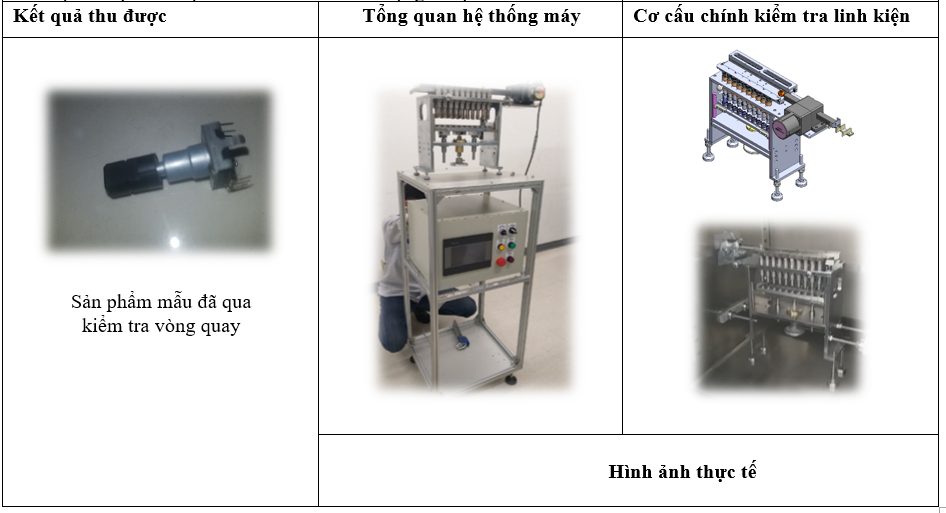

Project name: Potentiometer Component Rotation Tester

Project items: Design, construction and assembly of potentiometer components rotation tester

Detailed introduction:

In order to ensure the accuracy and quality of product processing, manufacturers must test and evaluate products before putting them into consumption. For potentiometer components in particular, manufacturers need to evaluate product life by means of rotation test under different environmental conditions. Therefore, Techcon provides customers with a rotary tester of potentiometer components with a compact and streamlined design, providing fast test results and increasing productivity for their industrial production lines. factory.

Working Principle:

The machine works based on the rack and pinion system, operating on the principle of converting from the rotation of the motor to the reciprocating motion. The components are arranged evenly into the jig mold, the screw pushes the mold so that it fits tightly with the clamp mold. Under the adjustable temperature range from -40oC to 70oC in the heating chamber, the machine system will turn the components left-right rotation with the allowed number of times (eg 30,000 revolutions/one test cycle). The machine has a control panel that allows the user to easily set the mode in accordance with the standard required by the supplier.

Technical improvements:

Manufacturers can simultaneously test 20 products in one test stage, the machine system helps to optimize, increase productivity and save costs for the product quality inspection process.