CUSTOMER INFORMATION

Customer name: Lixil Vietnam Co., Ltd

Address: Yen Binh Hamlet, Duong Xa Commune, Gia Lam District, Hanoi

PROJECT INFORMATION

Project name: Air leak tester in products

Project items: Design, construction and assembly of gas leak testers in products

Detailed introduction:

In order to ensure the accuracy and quality of product processing, manufacturers must test and evaluate products before putting them into consumption. Today, equipment with high vacuum systems is being used a lot in institutes, R&D centers and even in production. Therefore, Techcon provides customers with a project of a gas leak tester by vacuum method, which is a necessary solution to ensure product surface quality.

Working Principle:

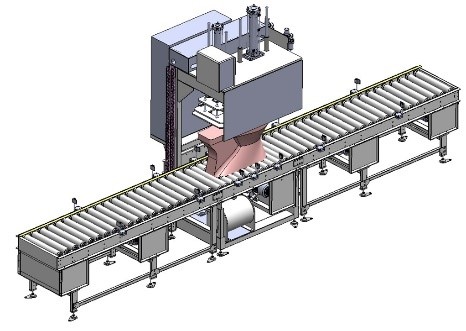

The machine works based on leak detection method by pressure drop test, meeting leak test requirements from raw vacuum to super high. By automatic conveyor system and sensors, the products to be tested are put into the inspection chamber in turn. Here, the compressed air cylinder system starts, presses the surface of the part, the pump begins to withdraw the vacuum and lock the valve. The pressure drop rate displayed on the gauge reflects the detailed leak level. The system has a control panel to help workers easily adjust the machine mode.

Technical improvement: Using PLC controller with conveyor system and pneumatic cylinder, the inspection process is optimized for machine operation, automation and improved productivity for manufacturers.

Chain overview: