Description

Features:

A powerful collection of highly concentrated mist up to 200mg/m3. The bestseller among electric collection Mist Collectors. Operational for both oil and water-soluble mist.

- The electronic trapping method keeps filter costs at zero

- Zero Filter Waste and No Filter To Clog

- High efficiency greater than 99%

- Small-capacity models

- For oil/water soluble mist collection

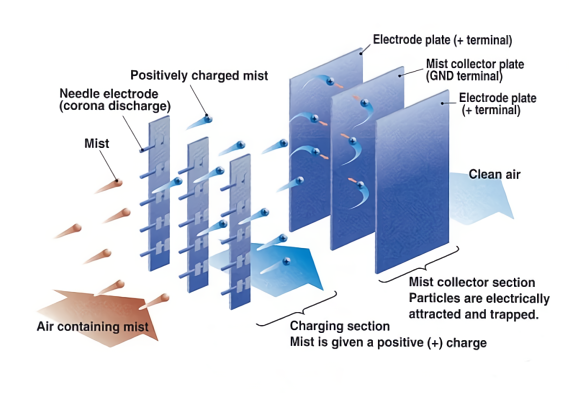

Breakthrough Electronic Trapping Method

Air-containing mist particles pass through the charging section having the corona effect, and those mist particles become positively charged. When this charged mist flows into the final stages of the mist collector, it is electrostatically attracted to the mist collector plate (ground electrode) where it is collected and trapped.

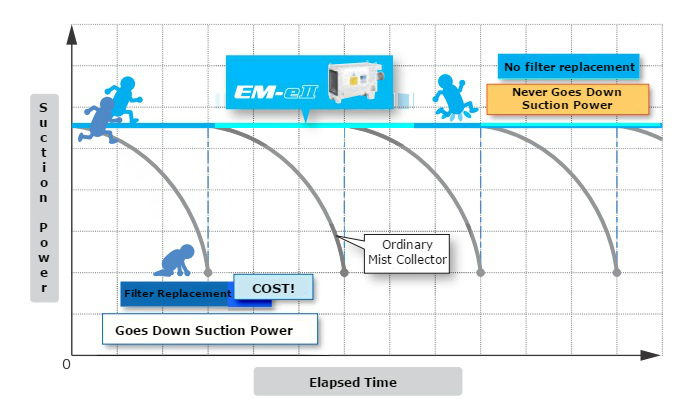

No Clogged Filter

Unlike the old filter method, there is absolutely no drop in air flow due to clogging so air flow is always stable during operation.

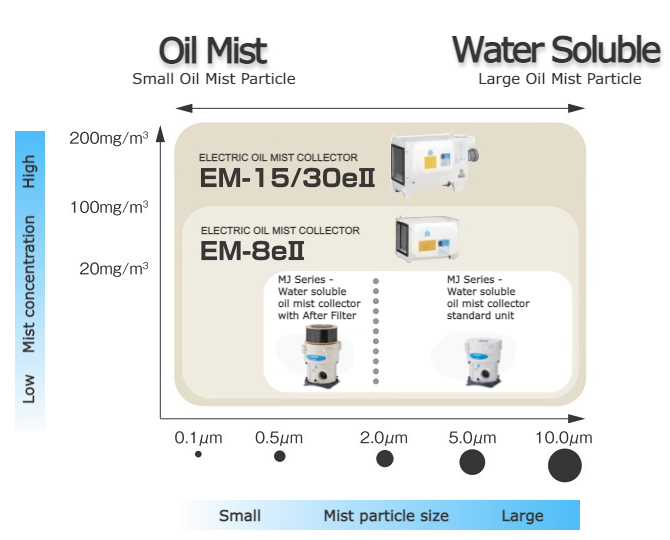

Difference Pure Oil mist and Water soluble oil mist

“OIL MIST” characteristic depends on the cutting fluid type (Water-based or Straight Oil). Oil mits are cutting fluid “vaporized” by heat. Water-soluble oil mist is when the cutting tools are physically “sheared” by the blade. Therefore, for water-based the mist particle is bigger than 2-10μm, while for straight oil the mist particle is smaller than 2μm and below. The particle size difference between water-based and straight oil is more than 10 times. And also the mist concentration is more than 10 times. If you are using straight oil as a cutting fluid, EM Series is the best choice.

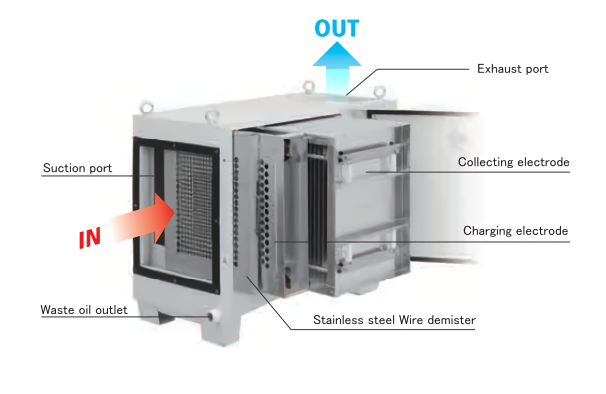

Internal Structure

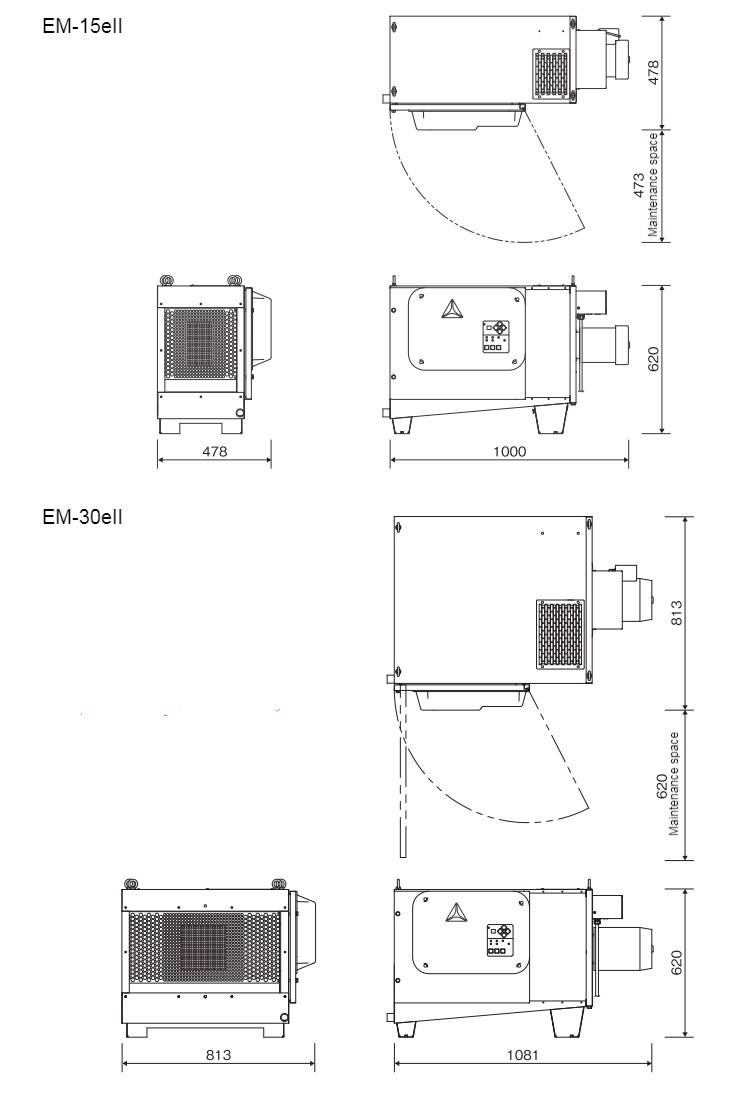

EXTERNAL VIEW

Unit: mm

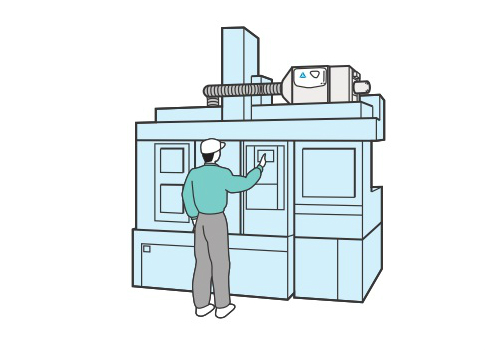

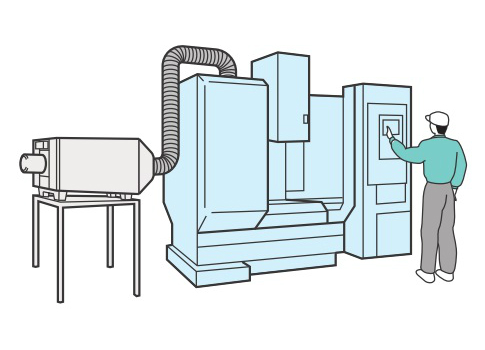

Application

Specifications

| Particular | Unit | EM-15eII | EM-30eII | |

|---|---|---|---|---|

| Power Supply | Volt | 220 | 220 | |

| Frequency | Hz | 50/60 | 50/60 | |

| Phase | 3-phase | 3-phase | ||

| Output | kw/hp | 1.5/2.0 | 2.2/3.0 | |

| Airflow (50/60Hz) | m³/min | 13.0/16.0 | 18.0/22.0 | |

| Static Pressure(50/60Hz) | kPa | 1.0/1.5 | 1.0/1.5 | |

| Suction Port Ø | mm | 150 or 200 | 200 or 250 | |

| Size(WxDxW) | mm | 478x1000x620 | 813x1081x620 | |

| Weight | kg | 70 | 115 |