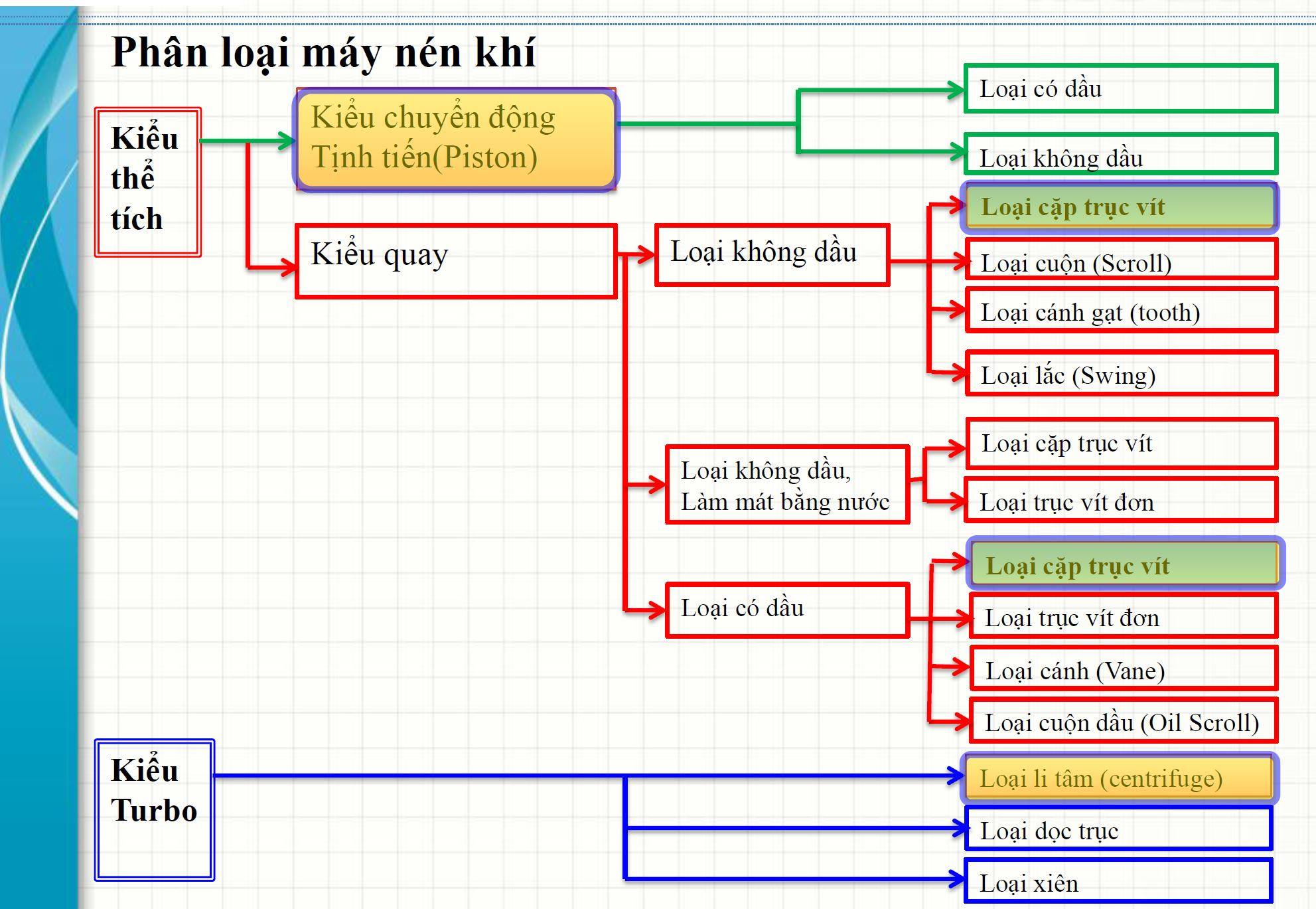

Because the air compressor is a device that generates a continuous flow of high-pressure air, there are many criteria to classify air compressors. In the scope of this article, we classify according to the criteria of compression chamber type, then there will be 2 main types: closed compression chamber type (also known as volumetric compression principle) and open compression chamber type (also known as the principle of accelerated compression).

1. Closed chamber compression type

A type of compression in which the chamber is closed during the compression process. The volume of the gas will change from a large volume to a small volume, through which the gas pressure will be increased. This is the traditional type of compression and is common in most air compressors today. With this type of compression, depending on the compression motion (rotary or translational), we have many types of corresponding air compressors.

A. Rotary Compression: This type is very common and comes in many varieties:

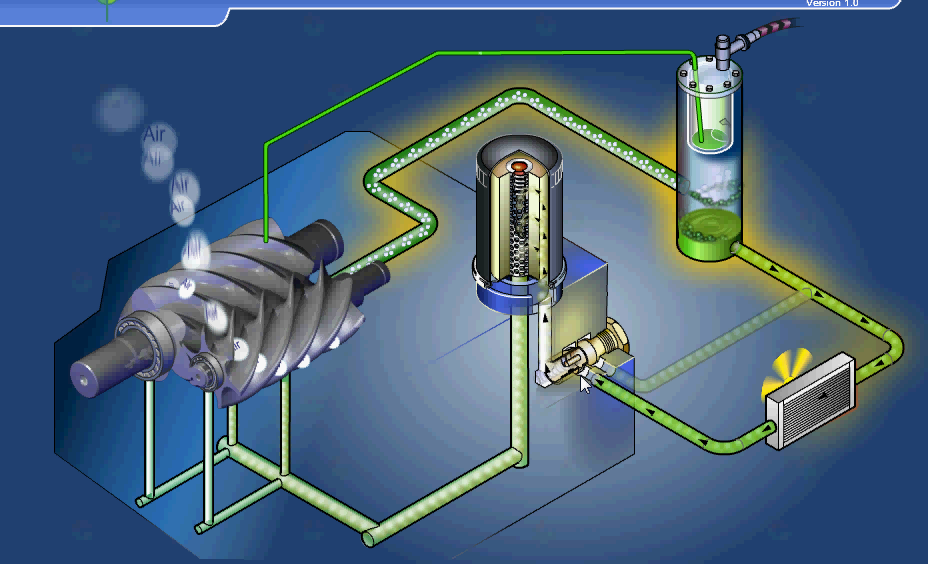

A1. Twin screw air compressor: Two screw will have a gap in the middle, this gap will be large at the suction end and small at the discharge end. The worm drive motor actively generates rotational motion. Then the airflow between the two screws will be led from the suction end (large gap) to the discharge end (small clearance). Because the gap is smaller, the volume of gas will become smaller, creating the process of air compression. Depending on whether there is oil or no oil in the compressor chamber, people are divided into oil-immersed screw compressors (Oil Flooded) or oil-free screw compressors (Oil-Free).

This twin screw air compressor series is the most popular line on the market today because it has many advantages such as high efficiency, continuous compressed airflow, quiet operation, easy automation, capacity. variety… However, this machine has the disadvantage of high investment cost, low pressure (Usually under 13 bar).

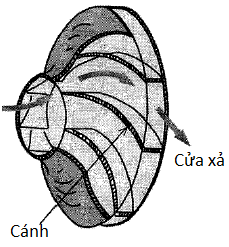

A2. Scroll compressor: Inside the compression chamber, there will be a structure of 2 staggered scroll wheels. When rotating, the gap between these two wheels will gradually decrease, creating the process of air compression. This series is suitable for small capacity, low pressure.In addition, the volumetric rotary movement has a few more but less common forms such as the single screw line (Compression between the screw and the compression chamber body), the vane line… Therefore, we do not introduce much about this line.

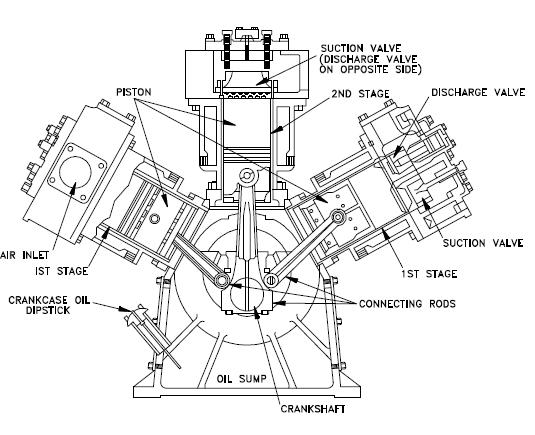

B. Compression with reciprocating motion (reciprocation or recipro for short): This is the oldest line of air compressors with the principle of piston-cylinder operation. Under the drive from the engine, the Piston will move to compress the air inside the cylinder. When the piston moves from the top dead center to the bottom dead center, the gas in the cylinder is compressed, creating pressure. The most primitive air compressor of this type is the bicycle hand pump that we often use.Piston series has the advantage of being compact, low cost, can compress to very high pressure, but has the disadvantage of very noisy operation, low efficiency, intermittent gas flow (Due to the piston return process, it will not labor). Therefore, this series is suitable for small power ranges (Usually less than 15 Kw). However, with the high pressure line, the piston machine can be designed with a very large capacity, possibly up to thousands of kW. Like the screw line, this line depends on the oil-free or oil-free compression chamber that people classify oil-immersed pistons and oil-free pistons.

2.Open chamber compression type

This is a special line of air compressors with an open-type compression chamber, which means there is no volume reduction process to generate pressure. This type of compression uses a large specialized propeller, which moves at extremely high speed to create a gas flow at a very high speed. This flow of gas will be caught in the receiving chamber and create gas pressure. Depending on the direction of the outlet gas flow, there are axial compression, cross compression and centrifugal compression.

According to dynamics research, in air compression technology, centrifugal compression type (Centrifugal) gives the highest efficiency, so at present, almost all turbo compressors are in the centrifugal form. That’s why people often call this compressor line turbo or centrifuge.

Due to the characteristics of the open turbo compression chamber, this machine cannot create too high pressure. However, the compression chamber can be designed in a large size, so this machine is often effective at large power ranges (Over 350 Kw).

Above is the basic classification of industrial air compressor lines, hopefully, can bring some basic knowledge to you. If you need further advice, you can leave a message and we will answer it carefully for you!