In the atmosphere, oxygen accounts for more than 20% and is the main cause of many oxidation phenomena:

- Oxidation of food, pharmaceuticals… thereby making products rancid, reducing quality and storage time

Is a good environment for bacteria to grow

- An indispensable element in the combustion process (Without oxygen, combustion cannot occur)

- With electronic components, semiconductors… that need to be preserved with high quality, oxygen should be removed because it will cause serious oxidation, reducing product life and quality

With the above effects of Oxygen, people have recently used High purity nitrogen to replace oxygen to preserve products. Nitrogen is colorless, odorless, tasteless and fairly inert and exists in the form of N2 molecules, also known as gaseous nitrogen. Therefore, it will slow down the growth of anaerobic microorganisms, prevent oxidation reactions, reduce pH or inhibit bacterial growth, prevent fire and explosion, and preserve metal from rusting due to oxidation. Oxidation…

Depending on the characteristics of the industry, the characteristics of Nitrogen will be selected appropriately:

1. In food technology: Most current foods are packaged and preserved by protective nitrogen (Bags of dried fruit, snacks, packaged meat and fish, canned foods, milk, yogurt, etc.), bottled fruit juice (non-carbonated)…).

- Nitrogen will be pumped into the product packaging at the final product packaging stage. Oxygen will be driven out almost 100%, replaced by almost pure Nitrogen (Purity used ranges from 99% to 99.99%).

- Nitrogen is injected into the packaging, in addition to the main function of preserving product quality, it also makes the packaging beautiful, making the product labeling process easy to manipulate, especially the automation process.

Due to the characteristic of extremely fast temperature change, nitrogen in many food fields can participate in cold storage.

2. In pharmaceutical technology: Medicines in the form of syrups… when produced, always need very high purity Nitrogen for preservation. With the characteristics of pharmaceutical products, Nitrogen has very high requirements for product quality.

- Requires very high purity (High purity), minimum of 99.9%, there are excipients that require nitrogen purity to preserve up to 99.999% to ensure complete prevention of the oxidizing effects of potential Oxygen

- Requires almost absolute nitrogen dryness (minimum dew point is -40 degrees Celsius, in some cases it is required to be up to -70 degrees Celsius)

- The cleanliness of the gas is at an absolute level, so in addition to the usual filters (1 micro dust filter, 0.01 micro-fine filter) it also needs a carbon deodorizing filter (0.003 wt ppm)

- Absolutely automatic packaging technology to avoid agents that cause oxygen contamination to the product

3. With electronic and semiconductor technology: In the process of manufacturing electronic components, semiconductors, medical equipment always requires a clean room, no dust. The oxidizing agents cause rust, making the product no longer retain the quality, mechanical properties and accuracy as designed, which in turn will lead to significant deviations in control and measurement… Nitrogen gas is used. Used to dry and preserve these components, helping them to stay at their best as designed. Purity in this field is usually chosen at 99% – 99.9%.

4. With metal cutting/welding technology: In metal welding/cutting, a very large heat flow will melt the metal in contact with it. Then the oxygen present in the air will quickly react with this molten metal to produce oxides. These oxides are responsible for creating rust layers, deforming materials, hardness, and durability of products. To overcome this point, people use inert gas to create a protective layer of gas around the weld/cut. Then the molten material will be isolated from the outside oxygen, helping the welding/cutting surface to keep the original material, shiny surface, and guaranteed product quality. Nitrogen with its inert properties and low cost is always preferred in this field, especially the very popular Laser cutting technology currently applied to stainless metal cutting. Purity will depend on the welding/cutting material. With laser technology for stainless steel, the purity usually requires 99.999%.

5. In testing and maintaining pipelines:

– Nitrogen gas is often used to test pipe leaks with high quality requirements. Due to its inert properties, the gas will not cause oxidizing rust on pipes and welds.– When the pipeline is not in use for a long time, people often inject nitrogen gas into it to preserve it. Thereby helping to keep the system safe for a long time.Nitrogen purity is not too high, usually around 95% ~ 98%.

6. In oil and gas exploitation: Oil fields will be sucked up for exploitation. However, when the reserve decreases, this will be very difficult to suck. At that time, people will pump some gas down to push the remaining oil reserves to the top, helping the suction process to take place smoothly. The gases used are inert gases, which prevent fire and explosion as well as have good compression performance. Nitrogen is the gas of choice because of all the above characteristics and low cost. Purity does not need to be too high, at about 98%.

7. In the brewing industry:

- In all breweries, large beer tanks will need to be cleaned before reuse. Nitrogen will be used to clean (flushing) the bottle, remove oxygen as well as not affect the quality of beer.

- In addition, nitrogen is also used to replace CO2 to pump into beer bottles/cans to preserve and maintain the freshness of beer, avoiding contact with oxygen, which causes beer to oxidize, ferment, and sour.

Purity in this field is quite high, about 99.9% or more.

8. Fire prevention: As we all know, combustion occurs when and only when there is enough oxygen. Therefore, for some flammable and explosive materials, storage must be in a rare atmosphere. At that time, people chose to pump nitrogen gas into the storage warehouse to minimize the risk of fire and explosion. Purity only needs to be as low as 95% to be guaranteed.

9. In addition, with supercars, airplanes … people also use nitrogen to pump into tires (tire). Nitrogen with low safety properties will keep the rubber layer less aging, the wheel metal less susceptible to rust. In addition, at high temperatures, it is less likely to expand, causing the risk of tire breakage.

Nitrogen gas in industrial production industries Nitrogen is a commonly produced and supplied gas product. On the market today there are K popular production methods:

- Method of fractional distillation of liquid air, then bottled for mass sale

- Super cold liquefaction method combined with molecular separation

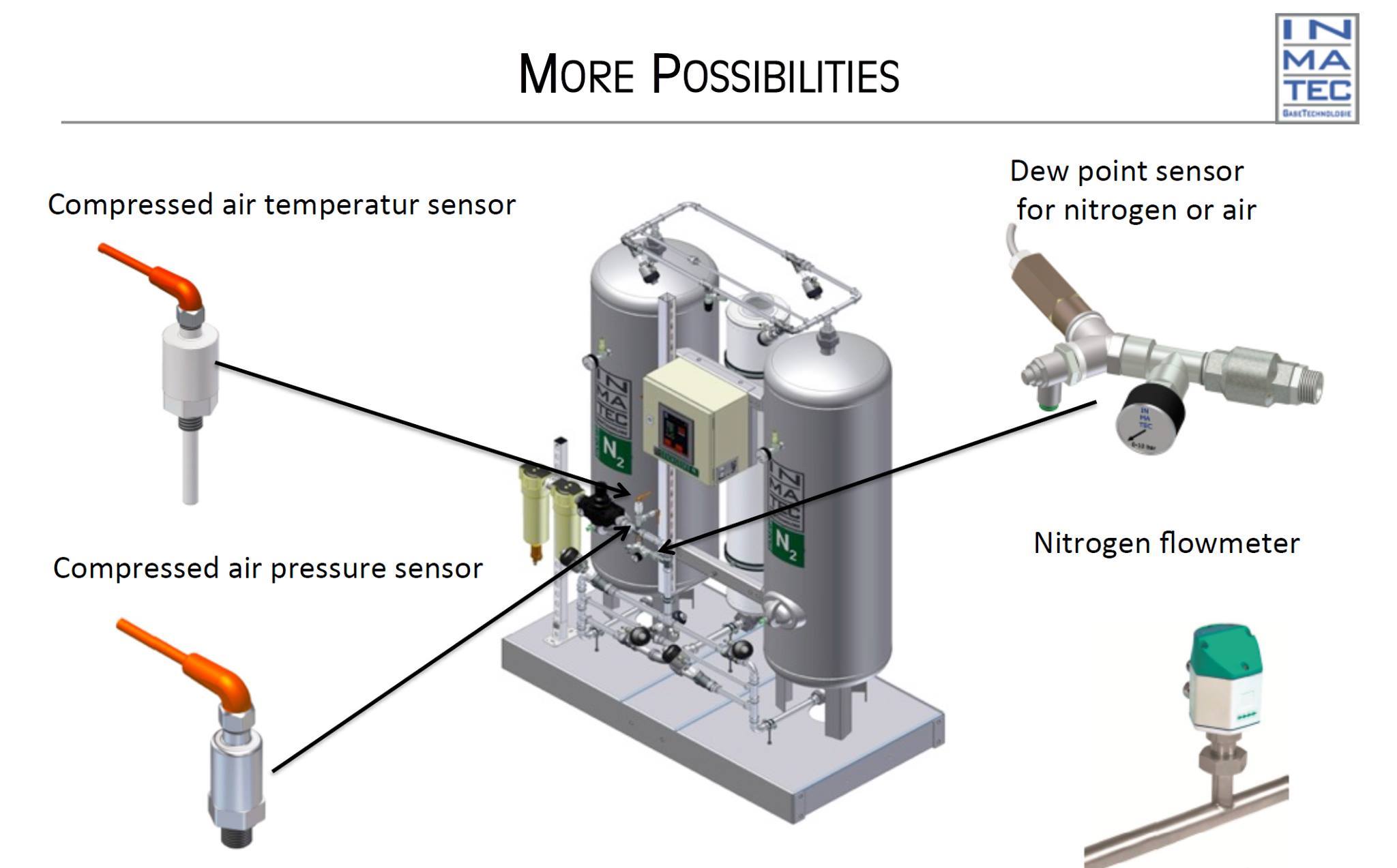

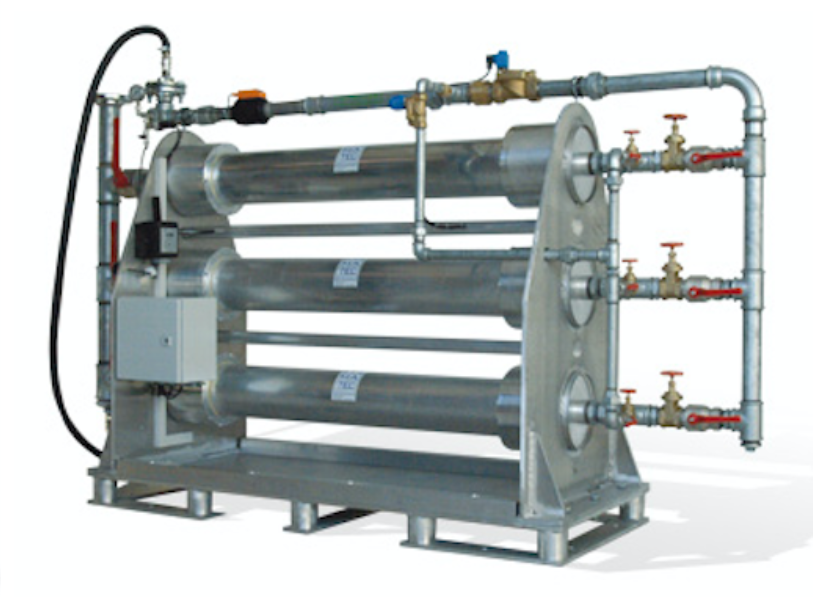

- Method of creating nitrogen gas by membrane technology (Membrane)

- The method of nitrogen gas generation by PSA (Pressure Swing Absorption) molecular separation technology