Oil in screw compressors has a very important role, but in summary there will be 4 main functions:

1. Lubrication function (Lubricated): Oil will be present in many parts (Compression chamber, bearing, oil separator…). In all these positions, the oil will directly participate in the lubrication process, helping the system operate smoothly, reducing friction and corrosion, and improving equipment life.

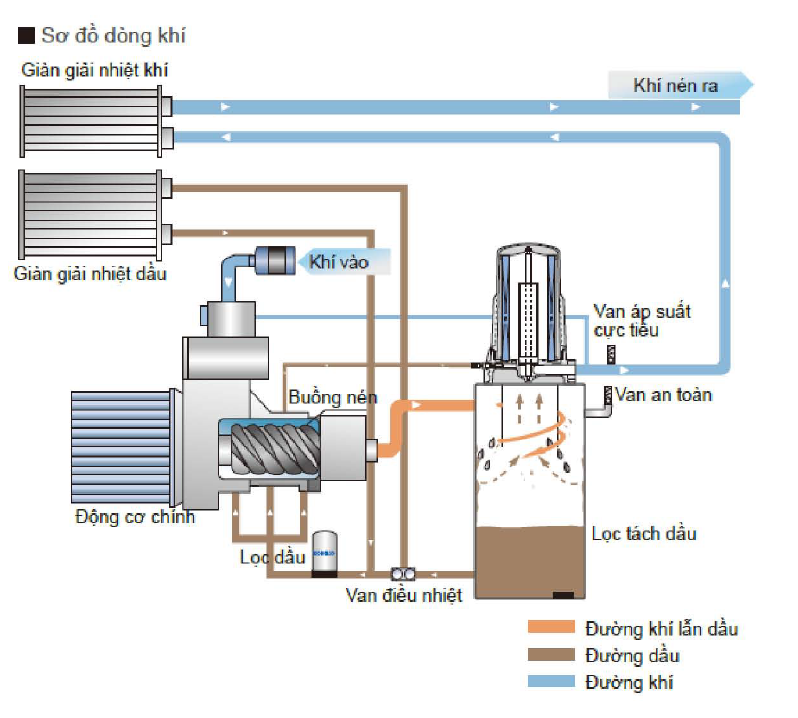

2. Cooling: The process of compressing air is the process of increasing the density of gas molecules. With a very high density, the gas molecules will constantly collide, resulting in huge heat generation. For air compressors with oil, the oil will mix with the air to participate in the compression process. Then the oil will take away a large amount of heat from the gas, helping the output compressed air to have a much lower heat. After being separated from the compressed air, the oil will be passed through the oil cooler (Oil Cooler) to be cooled before returning to the compression chamber to participate in a new cycle.

3. Sealed: The process of air compression is the process of creating gas flow from low pressure (intake) to high pressure (exhaust). This is the process of converting energy from electricity (forced rotation of the motor) to increasing pressure. However, the high-pressure air flow at the outlet always tends to flow back to the low-pressure area (inlet), this process is called pressure backflow. This process significantly reduces the compression efficiency. For oil-based air compressors, the compressed mixture is oil and gas, so oil with a viscous nature (Liquid, Viscous, high density) will seal the gaps between the screw slots, thereby obstruct this pressure reflux process, helping to absolutely improve the compression efficiency.

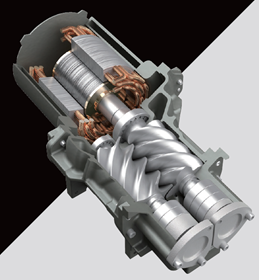

4. Drive: With twin screw air compressors, the two screws will always have a gap to store compressed air. The active screw will receive the movement from the motor through the transmission mechanism (Direct, gear, belt…). With oil lines, the oil will play an important role in transferring the motion from the active screw to the passive screw: The rotating active screw will press into the oil, the oil will press the passive screw blade. Thus, although the two screw shafts are not in contact with each other, there is no transmission mechanism, but through the oil, the movement is performed smoothly and smoothly.

With the above 4 functions, oil plays an important role in the operation of the air compressor. Oil has a role like blood in the human body. Therefore, it is important to change the oil of the right type, at the right time, clean the machine to avoid dust contamination, change the oil-related materials (oil filter, oil separator, oil recovery valve, thermostatic valve… ) will determine the safe and efficient operation of the air compressor!

You may not know, about 90% of air compressor failures are directly or indirectly related to lubrication!