Description

PRODUCT LEAFLET

THE ALL-ROUNDER FOR COUNTLESS VACUUM APPLICATIONS

Reliable

Robust construction, highly resilient carbon fiber vanes, proven rotary vane technology, long service life

High performance

High pumping speed at low pressures, designed for continuous operation in the rough vacuum range

Flexible

Various design options available, easy adaption to individual customer requirements and processes

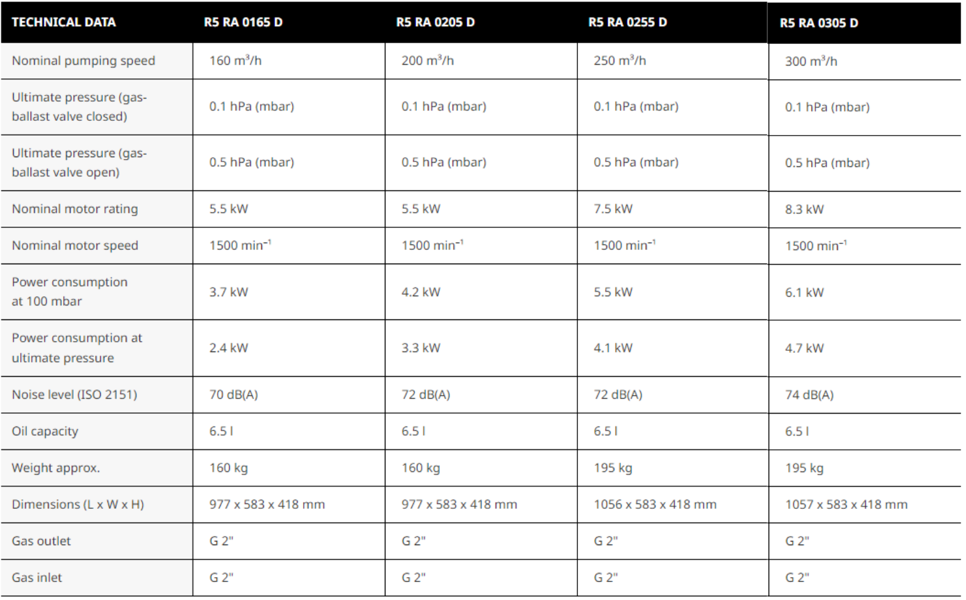

Technical specifications

ISO 50 Hz

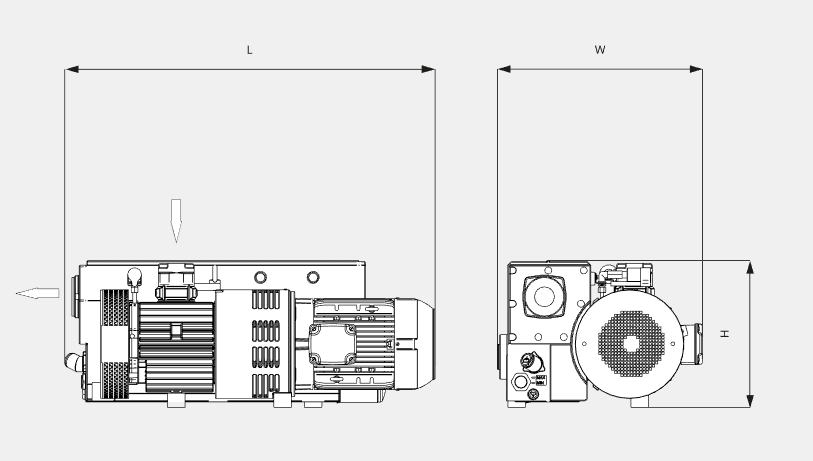

Dimensional drawing

R5 RA 0165–0305 D

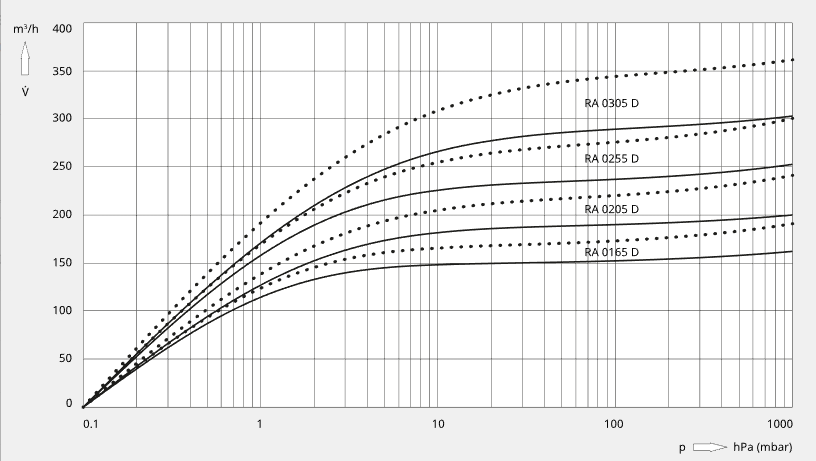

Pumping speed

Air at 20 °C. Tolerance: ± 10%

Markets & applications

Analytics and R&D

-

Freeze drying

-

Evaporation

-

Coating

Biogas handling

Upgrading – pressure swing adsorption

Chemical and pharmaceutical industries

-

Filtration

-

Evaporation

-

Distillation

-

Freeze drying

-

Drying

-

Solvent recovery

-

Pneumatic conveying

Electric power generation

-

Transformer oil purification

-

Transformer drying

Food processing

-

Pasteurizing

-

Sterilizing

-

Meat fillers

-

Freeze drying

-

Powder processing

-

Vacuum cooling

-

Meat marinators

-

Meat tumblers

-

Meat cutters

-

Beverage filling

-

Pneumatic conveying of wet food waste

Hospitals and healthcare facilities

-

Vacuum-assisted closure (VAC)

-

Medical suction

-

Surgical vacuum draining

Lithium ion battery production

-

Pick and place

-

Drying

-

Electrolyte filling

-

Slurry mixing

-

Degassing

Oil and gas industry

Pipeline drying

Packaging

-

Round-table/Carousel packaging machines

-

Blow molding

-

Liquid packaging

-

Blister packaging

-

Cartoning machines

-

Tray loading systems

-

Tray sealers

-

Thermoforming packaging machines – Forming station

-

Thermoforming packaging machines – Sealing/evacuation station

-

Chamber packaging machines large, industrial

Plastics processing

-

SSP recycling

-

Vacuum bagging

-

Pneumatic conveying

-

Injection molding

-

Thermoforming

Wastewater treatment

-

Vacuum sewerage

-

Vacuum disposal

Woodworking

-

Laminating presses

-

Feeding systems

-

Thermoforming

Accessories

- Gas-ballast valve

- Various inlet filters

- Energy recuperation kit with heat exchanger

- Oil level switch

- Temperature sensors

- Filter pressure gauge

- Vacuum pump oils for all applications

- Vacuum regulating unit

Design options

ATEX – for use in explosion hazard areas.