Description

WHY BUSCH GENUINE EXHAUST FILTERS?

Cost savings

- Low backpressure improves energy efficiency

- 99% of the expelled oil is captured and returned to the system, making fewer oil refills necessary

- Fine filtration material fills slower than a conventional filter, extending changing intervals

Better working environment

- Cleaner air

- Reduced noise level

- Lower temperature in the pump’s vicinity

Superior performance

- No negative impact on ultimate pressure throughout the filter’s lifetime

- Minimum flow resistance reduces load on the vacuum pump

- Stable filtration performance, whatever the application

SIGN OF QUALITY

Busch genuine exhaust filters are all subject to comprehensive testing during production. Each has its own signature of origin, making it fully traceable.

This gives you the security of knowing that you are using exclusively genuine Busch parts – and that you are maintaining your product warranty.

HOW OIL FILTRATION WORKS

In normal operation, an oil-lubricated vacuum pump creates a fine oil mist that becomes suspended in the air. The exhaust filter stops these particles from being expelled from the vacuum pump.

The oil particles coalesce on the interior of the filter element and are recycled back into the vacuum pump. Oil emissions to the ambient air are therefore reduced to an absolute minimum. This keeps backpressure low and leads to greater energy efficiency due to minimized flow resistance.

TECHNICAL BENEFITS OF BUSCH GENUINE EXHAUST FILTERS

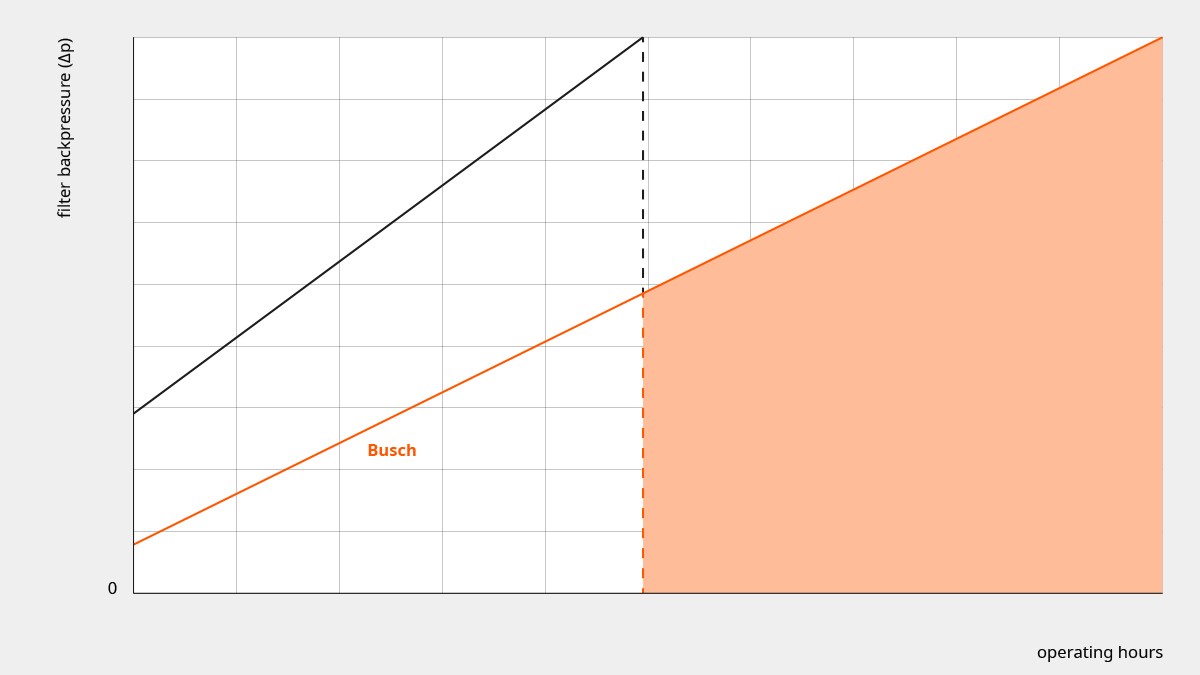

Filter backpressure

Conventional filter materials and designs (black line) fill with oil faster than a Busch genuine exhaust filter (orange line). The filter backpressure increases rapidly, which leads to a decrease in air flow through the exhaust.

A conventional filter also reaches its maximum permitted backpressure after a lower number of operating hours. As a result, they have a shorter service life and need to be changed more frequently.

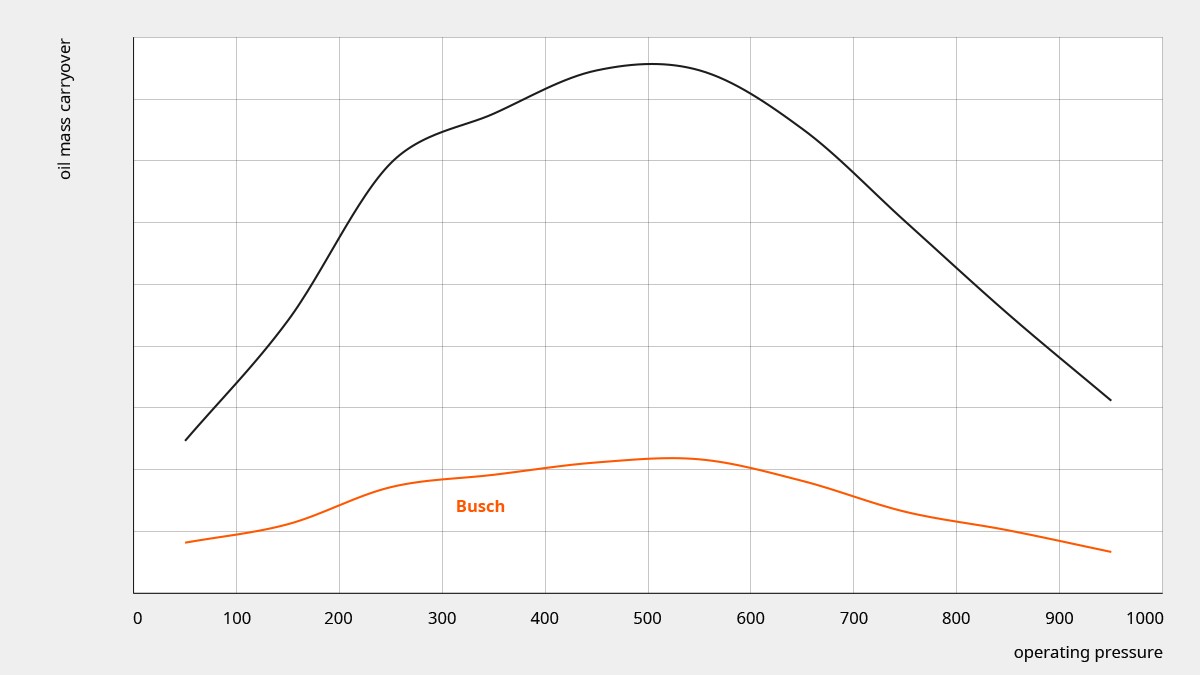

Oil mass carryover

The ultra-fine filtration medium and tight mesh in Busch genuine exhaust filters (orange line) catch more oil than conventional filter materials and designs (black line). This means significantly lower oil mass carryover at all operating pressures and a cleaner working environment.

THE RIGHT EXHAUST FILTER FOR EVERY APPLICATION

They are suitable for oxygen-rich applications and have high tolerance to harsh chemicals. Their highly conductive design prevents the risk of ignition through electrostatic discharge. For processes in explosion hazard areas, special exhaust filters suitable for ATEX-certified vacuum pumps are available.

HOW TO CHANGE EXHAUST FILTERS

Changing your exhaust filter should not be a challenge. Busch genuine exhaust filters are easy to remove and install. Our video demonstrates how you can carry out the process on an R5 vacuum pump.

With worldwide distribution, you can always get the parts quickly when you need them. We also offer support around the globe: Should you need help changing your exhaust filter, or you would like us to take care of your servicing, we are never far away.

Busch offers different service contracts, so you can hand over responsibility for your vacuum supply to us. Meaning that you can avoid downtime and keep your process running efficiently.