Description

PRODUCT LEAFLET

RELIABLE VACUUM FOR A VARIETY OF CHEMICAL PROCESSES

Robust

Proven technology, durable single-stage construction

Reliable

Extremely high vapor and particle tolerance

Flexible

Wide range of construction materials, including cast iron (EN-GJL-200), many grades of stainless steel and even titanium, ATEX-certified version available (Cat 1(i)/2(o) IIC T5), different operating fluids possible, operation as compressor possible

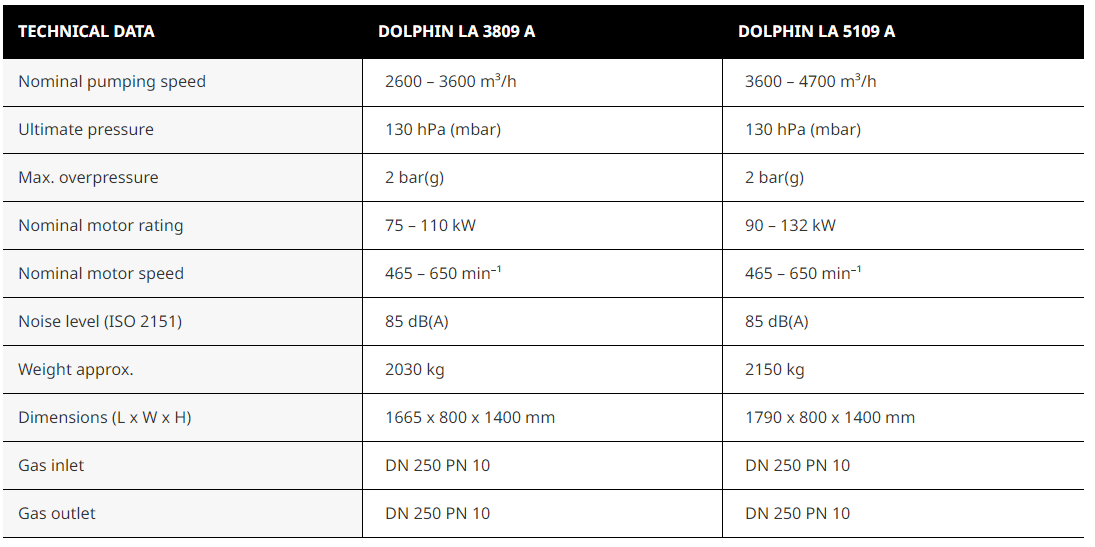

Technical specifications

ISO 50 Hz

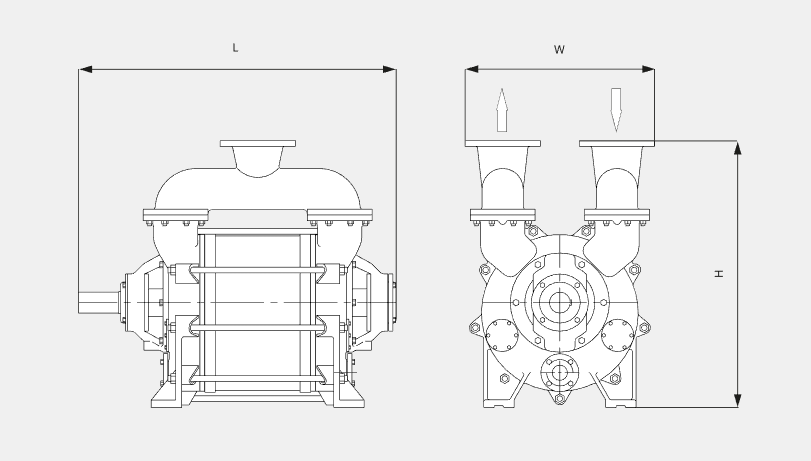

Dimensional drawing

DOLPHIN LA 3809/5109 A

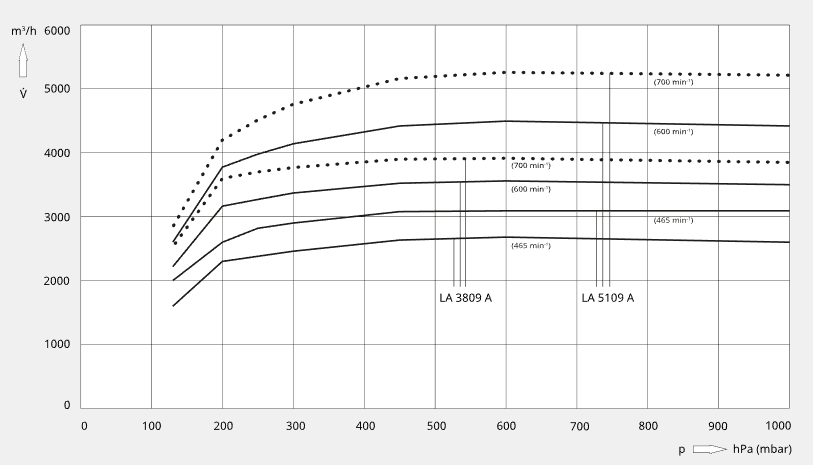

Pumping speed

Dry air at 20 °C. Tolerance: – 10%, in accordance with HEI and Pneurop 6612

Markets & applications

Chemical and pharmaceutical industries

-

Filtration

-

Evaporation

-

Distillation

-

Drying

-

Solvent recovery

-

Pneumatic conveying

Electric power generation

-

Geothermal gas extraction

-

Flue gas desulphurization (FGD)

Oil and gas industry

-

Mud drying

-

Water pump priming

-

Water degassing

-

Mud transfer

Packaging

Liquid packaging

Steel degassing

Vacuum degassing as backing pump for multi-stage steam ejector systems

Vapor recovery

-

Railcar and truck loading

-

Storage tank venting

-

Storage tank filling

-

Vapor balancing

-

Volatile organic compounds (VOC) recovery

Woodworking

Impregnation

Accessories

- Partial or total recirculation systems

- Liquid separator

- Cavitation protection

- Heat exchanger

- Gas ejector

- Wide selection of motors

- Non-return valves

- Vacuum relief valves

Design options

ATEX – for use in explosion hazard areas.