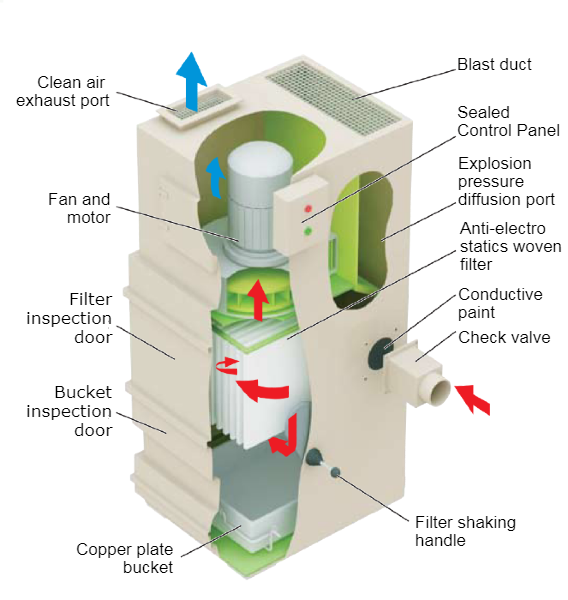

Description

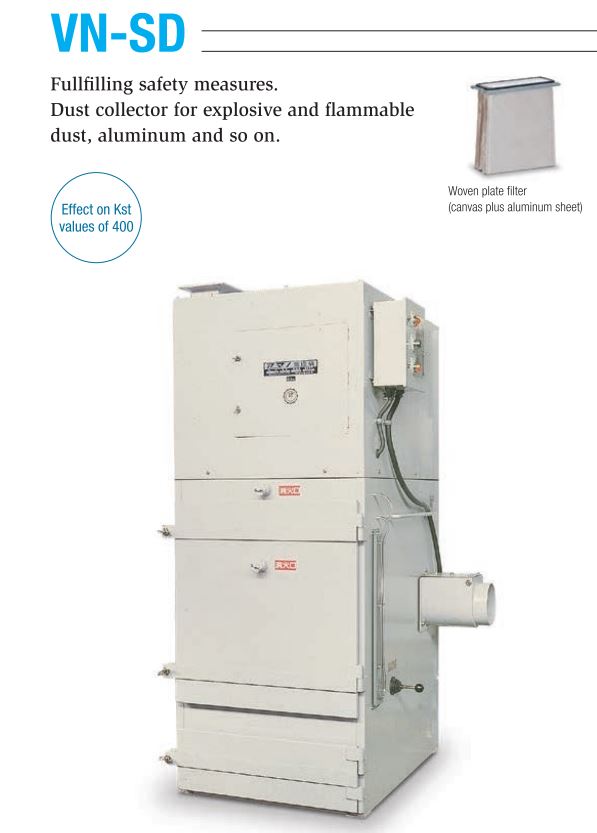

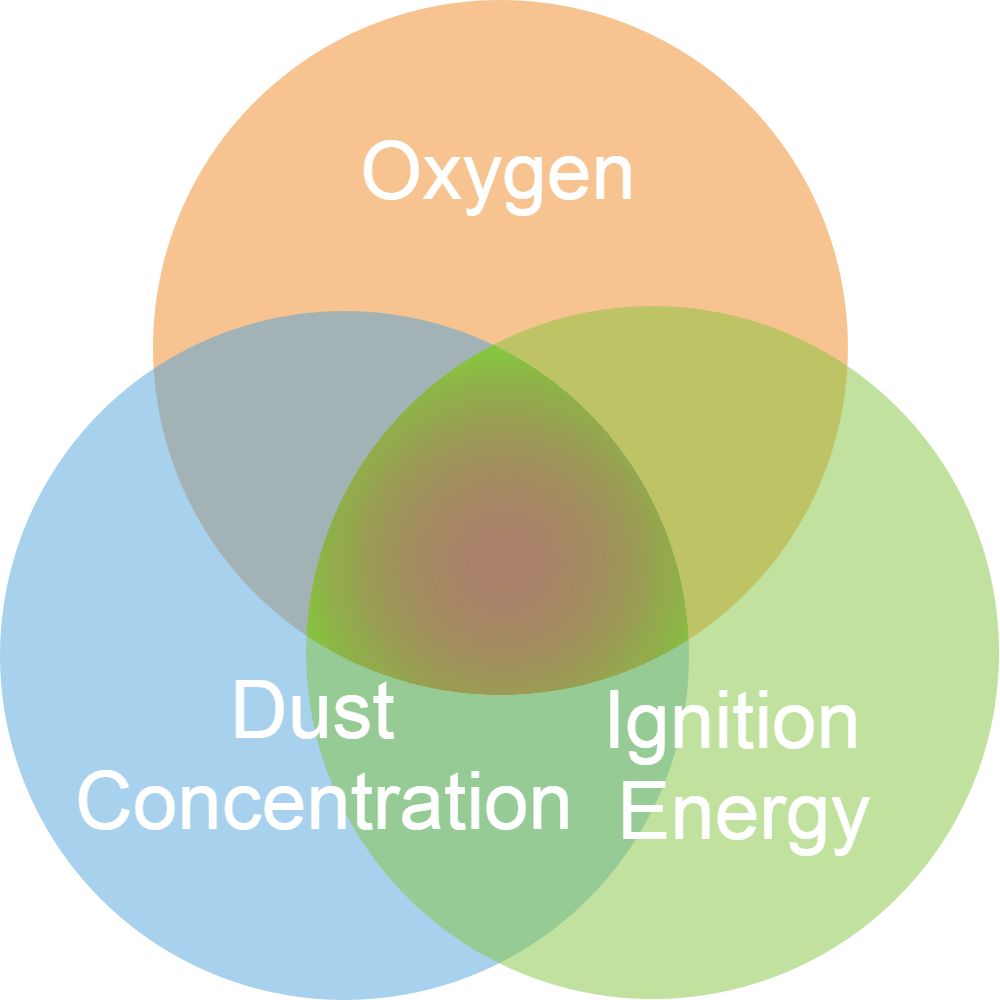

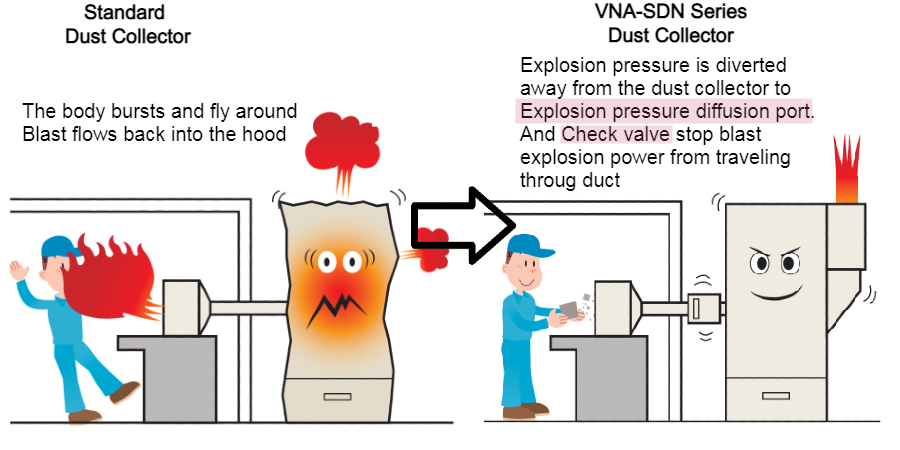

Bụi cháy là một trong những rủi ro nghiêm trọng nhất trong hầu hết các nhà máy sản xuất. Khi bụi nổ trở thành nồng độ oxy thích hợp và tiếp xúc với nguồn gây cháy sẽ gây nổ bụi. Một vụ nổ bụi có thể xảy ra ở nhiều khu vực của nhà máy sản xuất, nhưng một trong những vị trí có thể xảy ra nhất là thiết bị hút bụi. Đó là bởi vì bộ hút bụi giữ bụi trong không khí giới hạn trong một không gian cụ thể. Một vụ nổ trong thiết bị hút bụi không được bảo vệ có thể làm nổ thân thiết bị hút bụi và đưa lửa, áp suất và các đường đạn nguy hiểm vào nơi làm việc. Điều này có thể gây thương tích nghiêm trọng cho nhân viên. Vì vậy, nếu bạn cần thu gom bụi nổ, máy hút bụi nên có chức năng phòng ngừa và bảo vệ bụi nổ.