Description

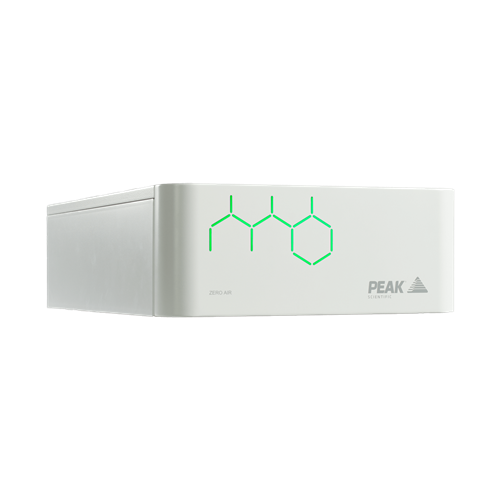

The Precision Zero Air generators are designed specifically to supply clean, dry, hydrocarbon-free air to be used as flame support gas for GC at both standard and trace detection limits.

As with all Precision series generators, Zero Air benefits from a compact and modular, stackable design, minimizing the total footprint required for GC gas supply, and providing flexibility to add or remove modules as your laboratory requirements evolve over time.

Features

- Integrates seamlessly with other Precision units Hydrocarbon content (as Methane) < 0.05ppm for market leading purity

- Minimum lifetime maintenance requirements, no expensive catalyst chamber replacements

- Avoid risk of contaminants entering the system (when switching out empty cylinders)

- No risk of running out of gas in middle of analysis

- Compatible with Precision Air Compressor

- Status indicative lighting feature (amber warm-up, green ready)

- 12 month comprehensive on-site warranty

Gas

Gas Type: Air

Max Gas Flow: 1.5L/min

Hydrocarbon Content: <0.05ppm

Max Output Pressure: 80psi/5.5bar

Site & Installation

Gas Outlets Fitting: 1 x 1/4″ BSPP

Min Inlet Pressure: 90psi/6.2bar

Max Inlet Pressure: 145psi/10bar

Min Air Inlet Flow: 1.5

Min Inlet Air Quality: ISO 8753-1:2010 Class 1.4.1 or Precision Air Compressor

Start Up Time: 60 mins

Power Consumption: 220 – 230 W

Voltage: 110 / 230 V

Frequency: 50 / 60 Hz

Current: 1 – 2 A

Heat output: 785

Accreditations: CE, CSA

Dimensions & weight

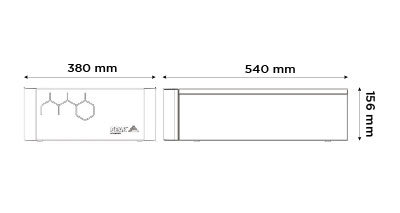

Size (HxWxD) mm: 156 x 380 x 540 mm

Size (HxWxD) mm: 156 x 380 x 540 mm

Size (HxWxD) Inches: 6.1 x 15 x 21.3 inches

Generator Weight: 16kg / 35.2lbs

Service Requirements

Annual replacement of particulate filters